Infuze™ Sanitary Cooking Skid

Infuze™ Sanitary Cooking Skid

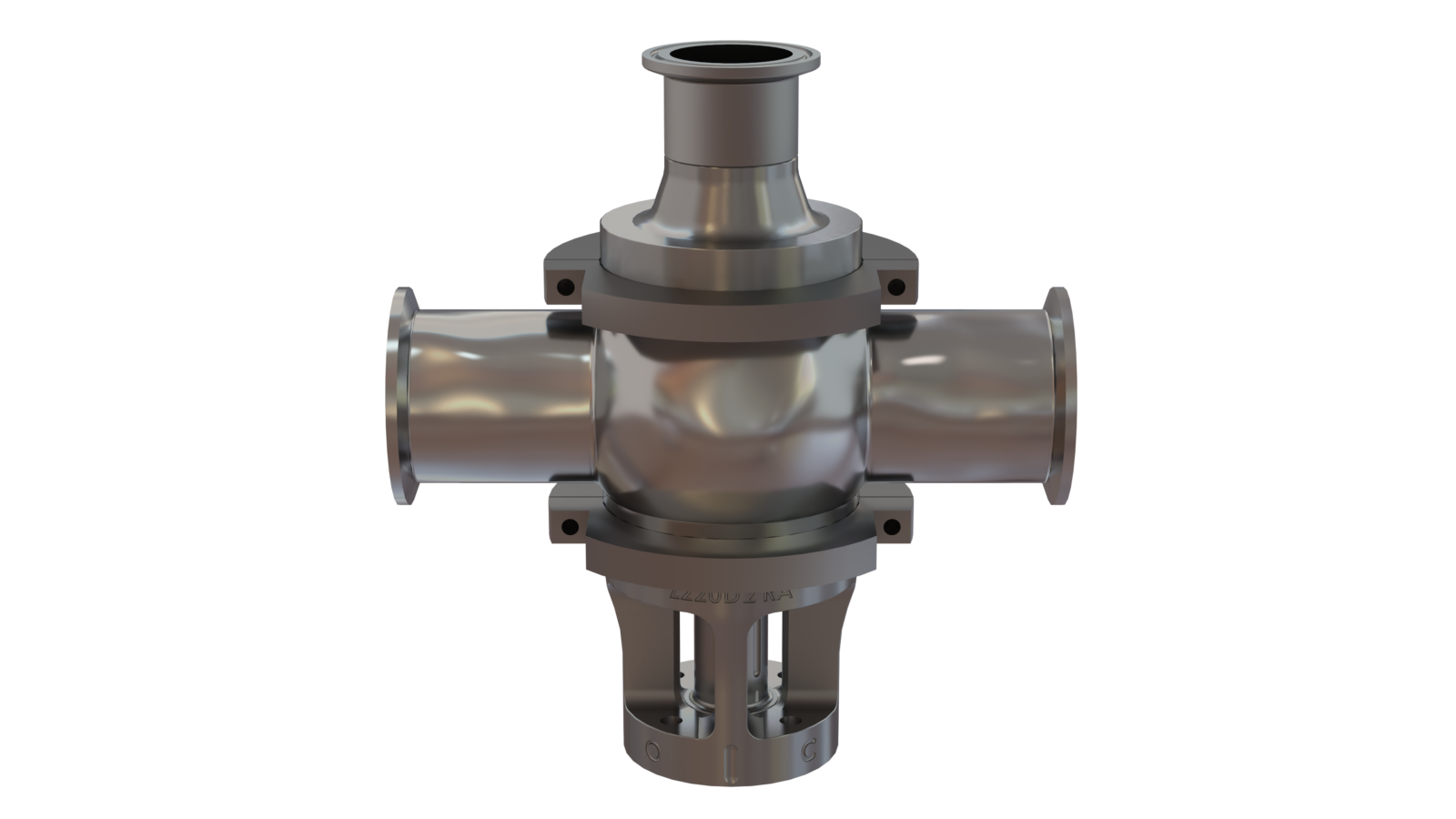

A member of the SilverLine family, the Infuze™ Sanitary Cooking Skid provides on-demand heating for soups, sauces, slurries or beverages that require heating to achieve finished recipe results, pasteurization or blended emulsification.

Pressure & Temperature

- Max pressure – 100 PSIG / 6.9 Barg

- Max temperature – 339°F / 170°C

Inlet/Outlet

- Tri-Clamp

Connection Types

- ANSI Class 150

- Other custom connections available

Sizing & Process Parameters

| Product Inlet/Outlet | 1.5″ / DN40 | 2″ / DN50 | 3″ / DN80 | 4″ / DN50 |

| Steam Inlet (in./mm) | 2″ / DN50 | 2″ / DN50 | 3″ / DN80 | 3″ / DN80 |

|---|---|---|---|---|

| Est. OA Width (in. /mm) | 31 / 788 | 31 / 788 | 31 / 788 | 31 / 788 |

| Est. OA Length (in. /mm) | 58 / 1,473 | 58 / 1,473 | 62 / 1,574 | 62 / 1,574 |

| Est. OA Height (in. /mm) | 77 / 1,955 | 77 / 1,955 | 77 / 1,955 | 77 / 1,955 |

| Min. Flow (GPM/m3/hr) | 3 / 0.7 | 5 / 1.1 | 12 / 2.7 | 22 / 5.0 |

| Max. Flow (GPM/m3/hr) | 30 / 6.8 | 60 / 13.6 | 140 / 31.8 | 255 / 57.9 |

Larger sizes are available upon request – contact the Hydro Thermal team for more information.

Maximize Your Process Potential

Don’t miss out on the benefits of ultra-precise, efficient, and reliable steam injection heating and cooking systems. Contact us today.