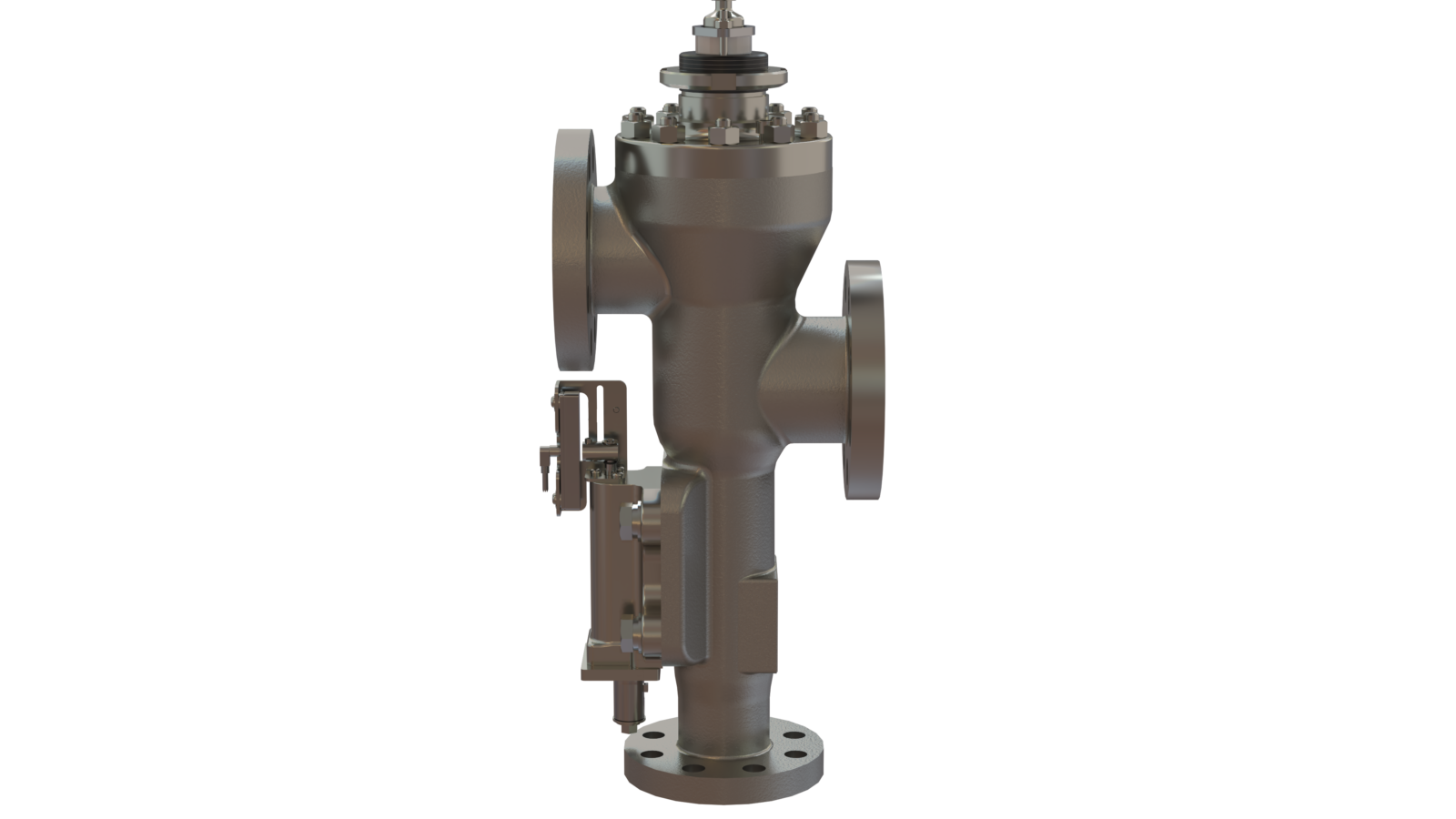

Hydroheater®/Jetcooker™

Hydroheater®/Jetcooker™

The Industrial Jetcooker™ is perfect for precisely heating liquids and slurries across varying viscosities and solids. Its unique combining tube adjustor allows easy control of process shear, making it ideal for optimal starch conversion.

Pressure & Temperature

- Max pressure – 300 PSIG / 20.7 Barg

- Max temperature – 450°F / 232°C

M-Series Hydroheater

- Max pressure – 300 PSIG / 20.7 Barg

- Max temperature – 450°F / 232°C

Flow Turndown

K-Series Hydroheater

- 3:1 turndown ratio (Water)

- 2:1 turndown ratio (Viscous Slurries)

M-Series Hydroheater

- 3:1 turndown ratio (Water)

- 2:1 turndown ratio (Viscous Slurries)

Connection Types

- ANSI Class 150 & Class 300

- DIN PN16, PN25, PN40

- Other custom connections available

Materials of Construction

- 316 Stainless Steel

- Other custom materials available

Sizing & Process Parameters

K-Series 2 1/2″-10″ / DN65-DN250

| K610 | K611 | K612 | K613 | K614 | K615 | |

| Steam Inlet (in./mm) | 2.5 63.5 | 3.0 76.2 | 3.0 76.2 | 4.0 101.6 | 6.0 152.4 | 8.0 203.2 |

|---|---|---|---|---|---|---|

| Process Inlet (in. /mm) | 2.5 63.5 | 3.0. 76.2 | 3.0 76.2 | 4.0 101.6 | 6.0 152.4 | 8.0 203.2 |

| Process Oulet (in./mm) | 2.0. 50.8 | 2.0. 50.8 | 2.5 63.5 | 4.0. 101.6 | 6.0 152.4 | 8.0 203.2 |

| Min. Flow (GPM/m3/hr) | 28.0 6.4 | 40.0 9.1 | 40.0 9.1 | 120.0 27.3 | 300.0 68.1 | 400.00 90.9 |

| Max. Flow (GPM/m3/hr) | 174.0 39.5 | 402.0 91.3 | 402.0 91.3 | 750.0 170.3 | 1,800.0 408.8 | 2,5000.0 567.8 |

| Weight (lbs./kg) | 160.0 72.6 | 297.0 134.7 | 305.0 138.4 | 447.0 202.8 | 704.0 319.3 | 934.0 423.7 |

Larger sizes are available upon request – contact the Hydro Thermal team for more information.

Maximize Your Process Potential

Don’t miss out on the benefits of ultra-precise, efficient, and reliable steam injection heating and cooking systems. Contact us today.