Silverline™ Smart Cooking System

Silverline™ Smart Cooking System

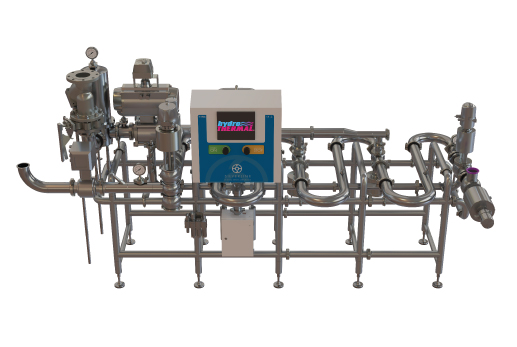

The SilverLine is a polished stainless steel system engineered to precisely replicate specified processing profiles. Despite its simple appearance, it incorporates thousands of hours of engineering into a single, advanced machine – acclaimed as one of the most advanced food and beverage processing systems globally.

Volume Capability

- 5 up to 200 gpm [1.1 up to 45 m³/hr]

Connection Types

- Tri-clamp

- Other custom connections available

Materials Of Construction

- 316L – Standard

- Other materials available

Sizing & Process Parameters

Larger sizes are available upon request – contact the Hydro Thermal team for more information.

Maximize Your Process Potential

Don’t miss out on the benefits of ultra-precise, efficient, and reliable steam injection heating and cooking systems. Contact us today.