Solaris® Hydroheater

Solaris® Hydroheater

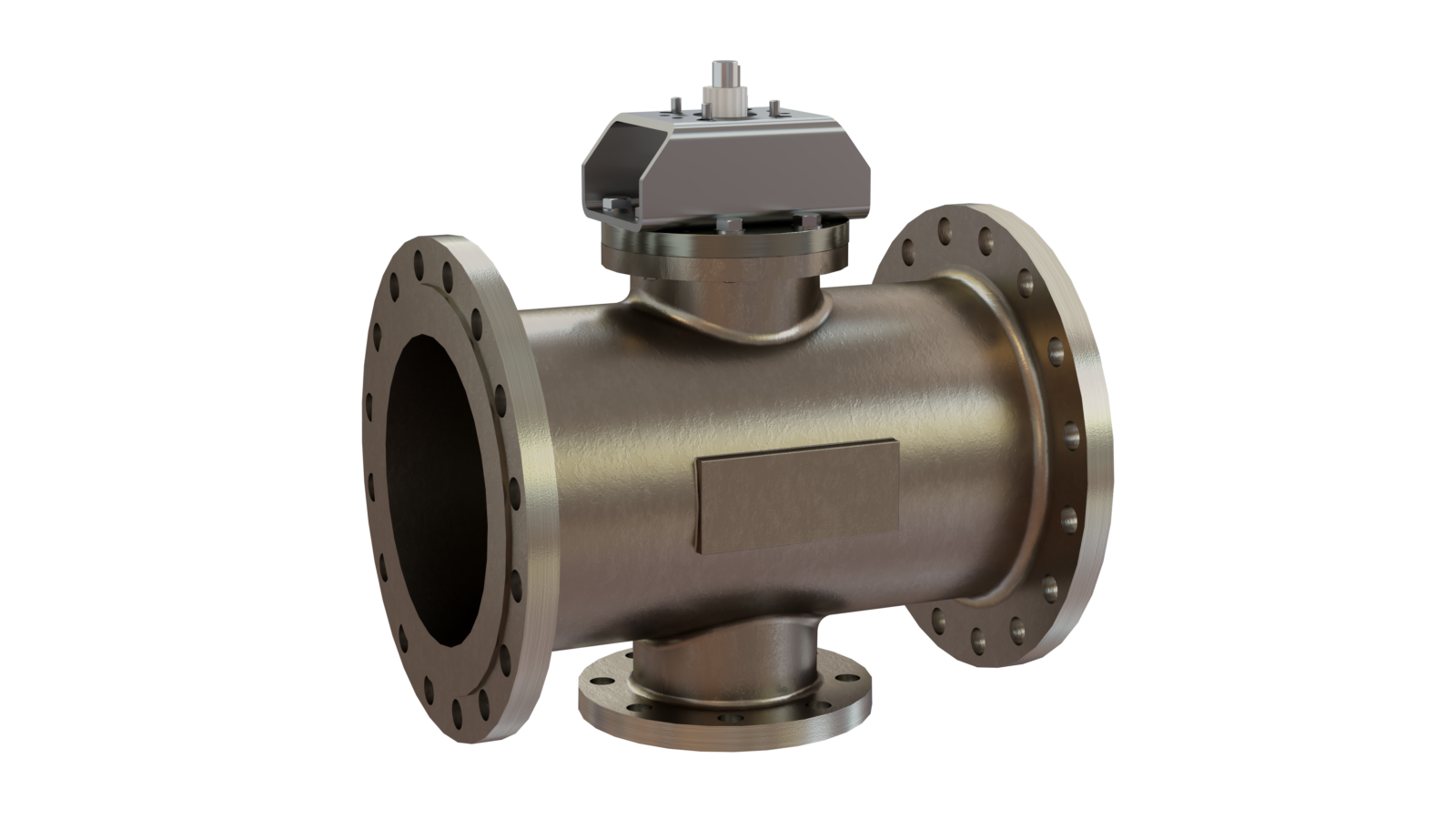

The Solaris® features a cross flow diffuser that injects steam across the entire cross-section of flow to ensure thorough mixing and a uniform temperature profile. It utilizes low shear flow, making it ideal for slurries with high solid contents and process fluids where chunk size must be maintained.

Pressure & Temperature

- Max Pressure – 300 PSIG / 20.7 Barg

- Max Temperature – 450°F / 232°C

Flow Turndown

- Up to 10:1 Liquid Turndown

Connection Types

- ANSI Class 150 & Class 300

- DIN PN16, PN25, PN40

Sizing & Process Parameters

| S203 | S204 | S206 | S208 | S210 | S212 | |

| Steam Inlet (in./mm.) | 2.5 64.0 | 2.5 64.0 | 4.0 102.0 | 4.0 102.2 | 6.0 152.4 | 6.0 152.4 |

|---|---|---|---|---|---|---|

| Process Inlet (in./mm.) | 3.0 76.2 | 4.0 102.0 | 6.0 152.4 | 8.0 203.2 | 10.0 203.2 | 12.0 304.8 |

| Process Outlet (in./mm.) | 3.0 76.2 | 4.0 102.0 | 6.0 152.4 | 8.0 203.2 | 10.0 203.2 | 12.0 304.8 |

| Weight (lbs./kg) | 105 47 | 134 61 | 235 106 | 287 130 | 346 157 | 519 235 |

| Max. Flow (GPM/m3/hr) | 180 41 | 600 146 | 1,300 296 | 2,200 500 | 3,700 840 | 5,000 1,136 |

Larger sizes are available upon request – contact the Hydro Thermal team for more information.

Related Literature

Maximize Your Process Potential

Don’t miss out on the benefits of ultra-precise, efficient, and reliable steam injection heating and cooking systems. Contact us today.