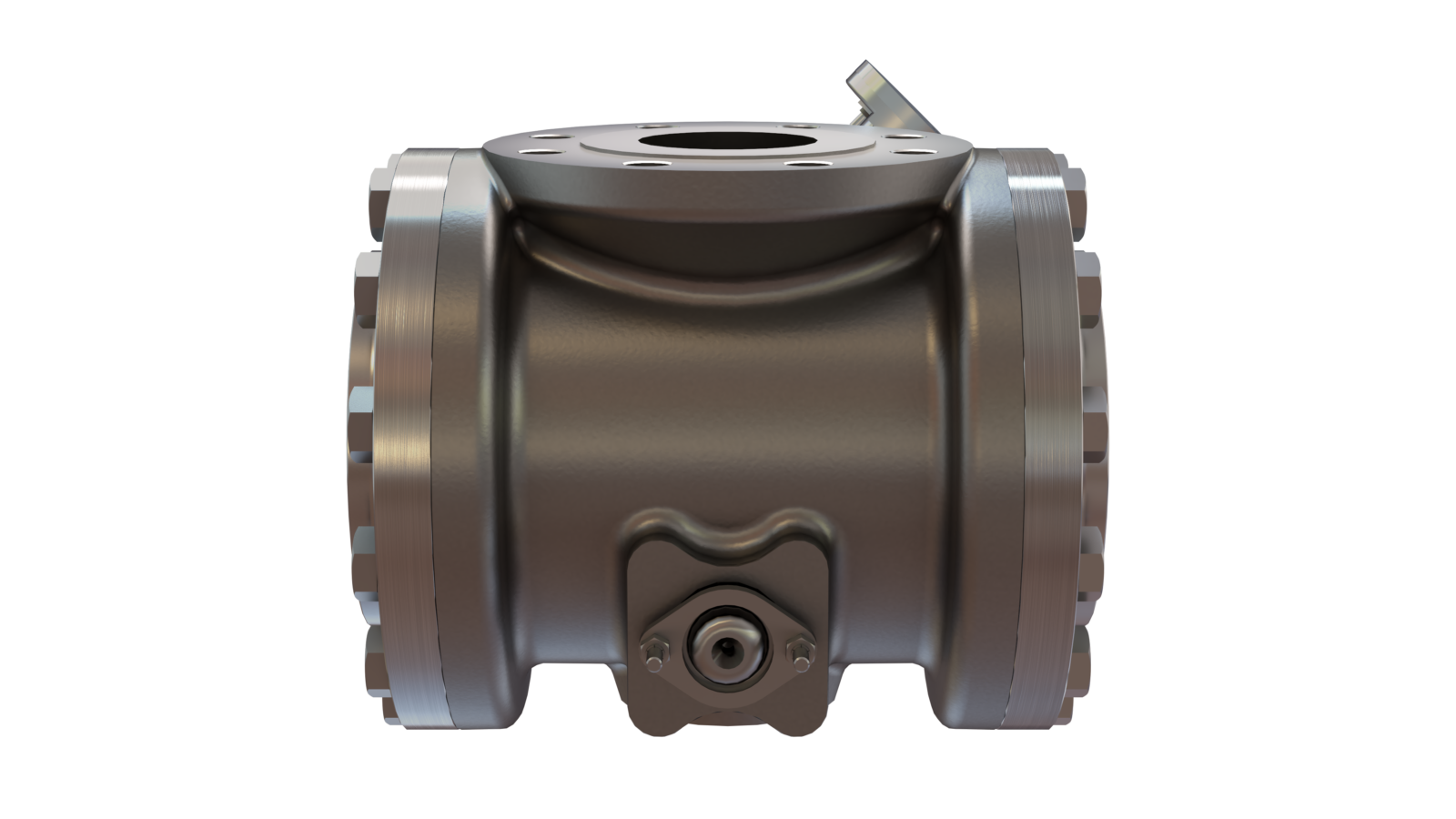

NOH™ (Non-Obstructing Heater)

NOH™ (Non-Obstructing Heater)

Hydro-Thermal’s innovative NOH’s straight tube design allows unrestricted flow, prevents pressure drop and heats slurries without plugging or fouling. The NOH’s rugged design and materials of construction allow it to handle abrasive materials minimizing wear on internal parts.

Pressure & Temperature

- Max Pressure – 300 PSIG / 20.7 Barg

- Max Temperature – 400°F / 204°C

Flow Turndown

- 5:1 Liquid Turndown

Product Inlet / Outlet & Steam Flange

- 300# raised face flanges designed

- (per ANSI B16.5) with lugged connections

Controls

- NOH can be locally controlled from the panel or from DCS. For Distributed Control System (DCS), either Ethernet IP, Modbus TCP, or limited analog and digital must be utilized.

Sizing & Process Parameters

| NOH02 | NOH04 | NOH08 | NOH12 | |

| Steam Inlet (in./mm) | 3.0 76.2 | 6.0 152.4 | 8.0 203.2 | 12.0 304.8 |

|---|---|---|---|---|

| Steam Drain (in./mm) | 0.5 12.7 | 1.0 25.4 | 1.0 25.4 | 1.0 25.4 |

| Estimated OAL Length (in./mm) | 12.0 304.8 | 10.0 482.6 | 24.0 609.6 | 33.5 850.0 |

| Estimated CL to Steam Flange (in./mm) | 5.0 127.0 | 6.5 165.1 | 8.0 203.2 | 11.66 296.2 |

| Min. Flow (GPM/m3/hr) | 30.0 6.8 | 110.0 25.0 | 455.0 103.4 | 1,035 235.1 |

| Max. Flow (GPM/m3/hr) | 175 39.7 | 735 167.0 | 3,063 693.4 | 8,900 1567.2 |

| Estimated Weight (lbs./kg) | 220 100 | 450 204 | 850 421 | 1900 862 |

Larger sizes are available upon request – contact the Hydro Thermal team for more information.

Related Literature

Maximize Your Process Potential

Don’t miss out on the benefits of ultra-precise, efficient, and reliable steam injection heating and cooking systems. Contact us today.