Overview

In the personal care industry, precise and efficient heating is essential for effective wastewater pretreatment is essential for industrial facilities to remove contaminants, reduce harmful pollutants, and meet regulatory standards before discharge or further processing. Many industrial pretreatment applications, such as sludge conditioning, coagulation, and biological treatment, benefit significantly from precise temperature control and consistent heat distribution.

Direct Steam Injection (DSI) heaters offer an efficient, reliable solution for these needs, helping improve pretreatment outcomes and reduce energy consumption in wastewater processing:

- Enhances biological activity by maintaining consistent, optimal temperatures, accelerating the breakdown of organic matter for faster, more efficient pretreatment

- Improves sludge conditioning with consistent heating, aiding in water separation, easier dewatering, and reduced disposal costs

- Optimizes coagulation and flocculation by ensuring stable temperatures, enhancing pollutant removal and helping meet discharge regulations

- Maximizes energy efficiency by direct steam injection, cutting heat loss and lowering fuel use for reduced operating costs

- Minimizes fouling and maintenance with direct heating, extending equipment lifespan and reducing downtime in wastewater treatment

- Speeds up chemical reactions for faster processing, reducing overall treatment time and boosting throughput capacity

- Reduces odors by breaking down volatile compounds, creating a cleaner and more pleasant working environment

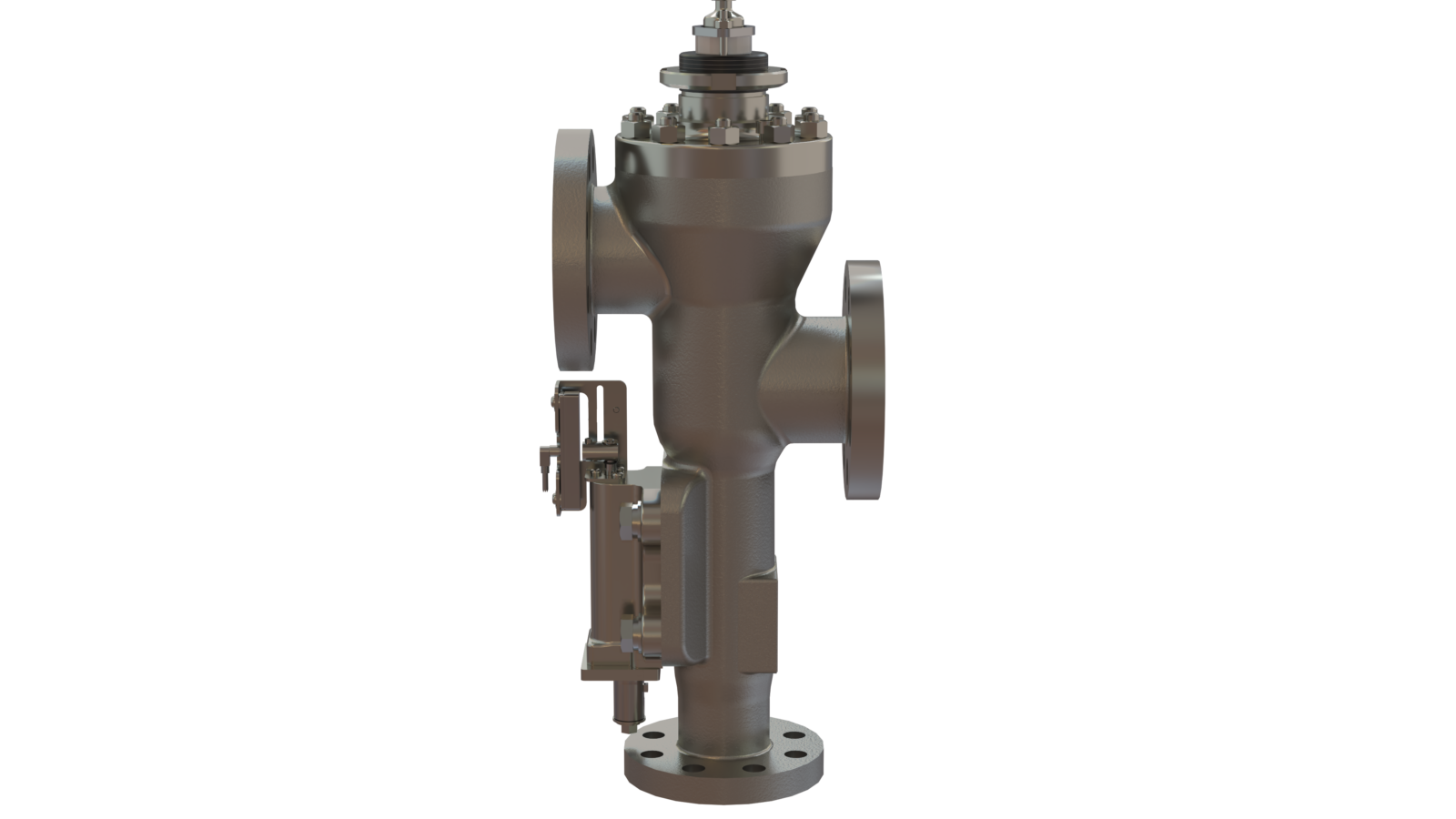

Hydroheater®

Also known as the Jetcooker™, our Hydroheater® has the longest proven history of heating and processing a complex range of liquids and materials. Known for its adjustability, durability, and power, the near century of engineering and innovation behind the design of this workhorse speaks for itself.

- Volume capability: 1 up to 6,700 gpm [0.2 up to 1,522 m³/hr]

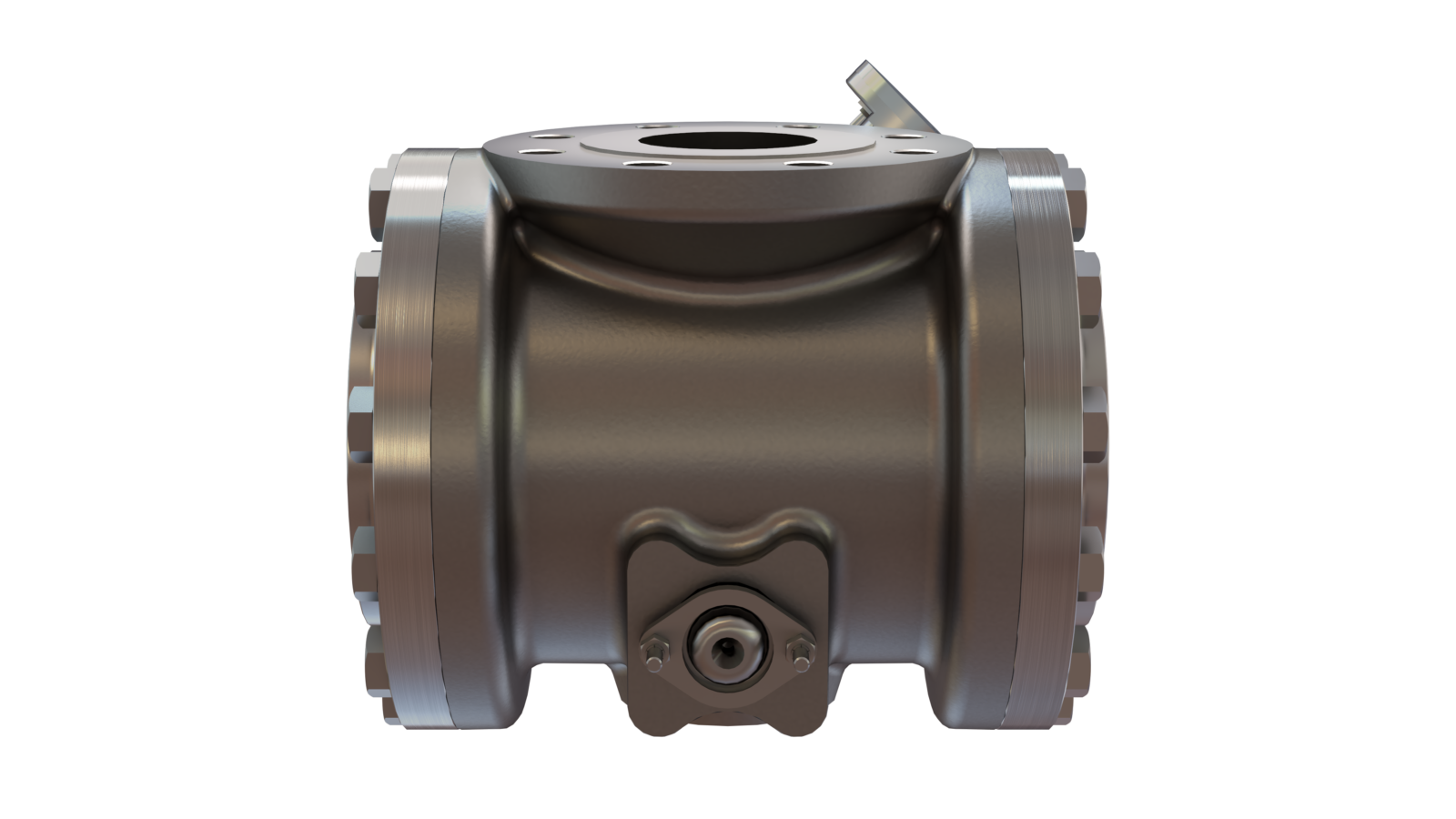

NOH™ (Non-Obstructing Heater)

The Non-Obstructing Heater is rugged enough to handle even the toughest abrasive materials, like sand and grit, to fibrous materials and large particulates.

- Its non-obstructive design protects against plugging, fouling, and pressure drop with its powerful, unrestricted flow.

- Volume capability: 30 up to 3,035 gpm [6.8 up to 689 m³/hr]

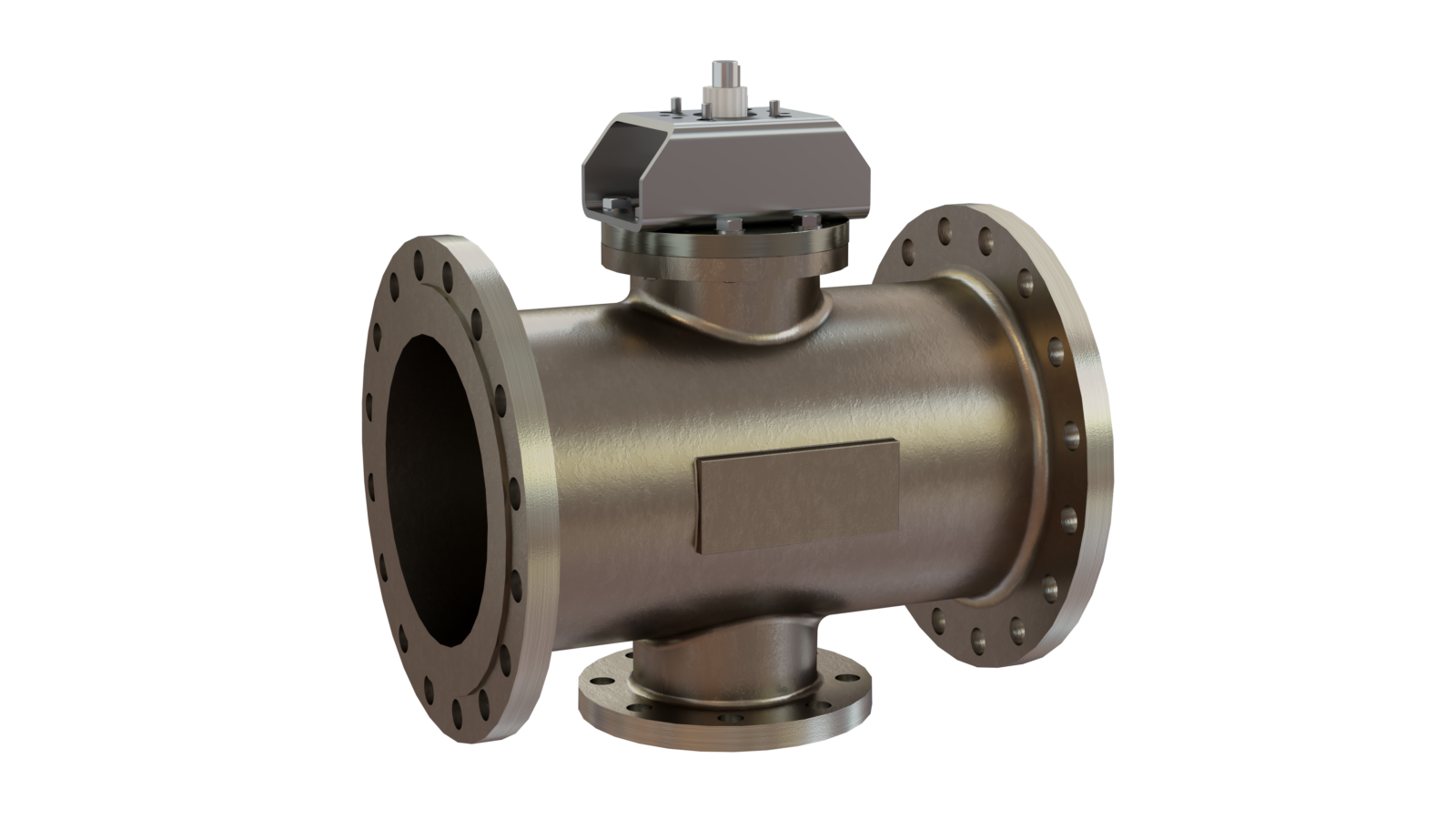

Solaris®

Perfect for viscous slurries, the Solaris® heater features an optimized straight-through design and low shear flow perfect for heavy slurries with medium consistency or higher solid contents. The flow diffuser injects steam across the entire cross-section to ensure thorough mixing and a uniform temperature profile even at a high volume and flow rate.

- Volume capability: 5 up to 25,000 gpm [1 up to 5,678 m³/hr]