Overview

Anaerobic digestion is a widely used process in the food and beverage, pharmaceutical, and chemical manufacturing industries to treat wastewater and organic sludge. This process reduces the volume of waste while producing valuable biogas that can be used as a renewable energy source. Consistent heating is crucial to maximizing the efficiency of anaerobic digesters.

Direct Steam Injection (DSI) heaters offer substantial advantages over traditional heating systems, improving process efficiency, lowering energy consumption, and ensuring optimal conditions for microbial activity:

- Rapid, uniform heating for anaerobic digesters, maintaining stable temperatures for optimal microbial activity and consistent biogas production

- Enhanced energy efficiency by eliminating heat transfer losses, reducing energy consumption and operating costs in large-scale digestion processes

- Increased biogas yield by maintaining precise temperatures, optimizing microbial activity for higher methane output and added renewable energy potential

- Reduced maintenance and downtime with fewer contact surfaces, minimizing fouling risks and lowering maintenance requirements

- Compact design for easy integration into existing systems, saving space and simplifying upgrades with minimal infrastructure modifications

- Enhanced process control with real-time temperature adjustments, ensuring stable digestion conditions even with varying sludge compositions

- Improved sludge dewatering and handling by rapidly heating sludge, reducing its volume for easier disposal and lowering handling costs

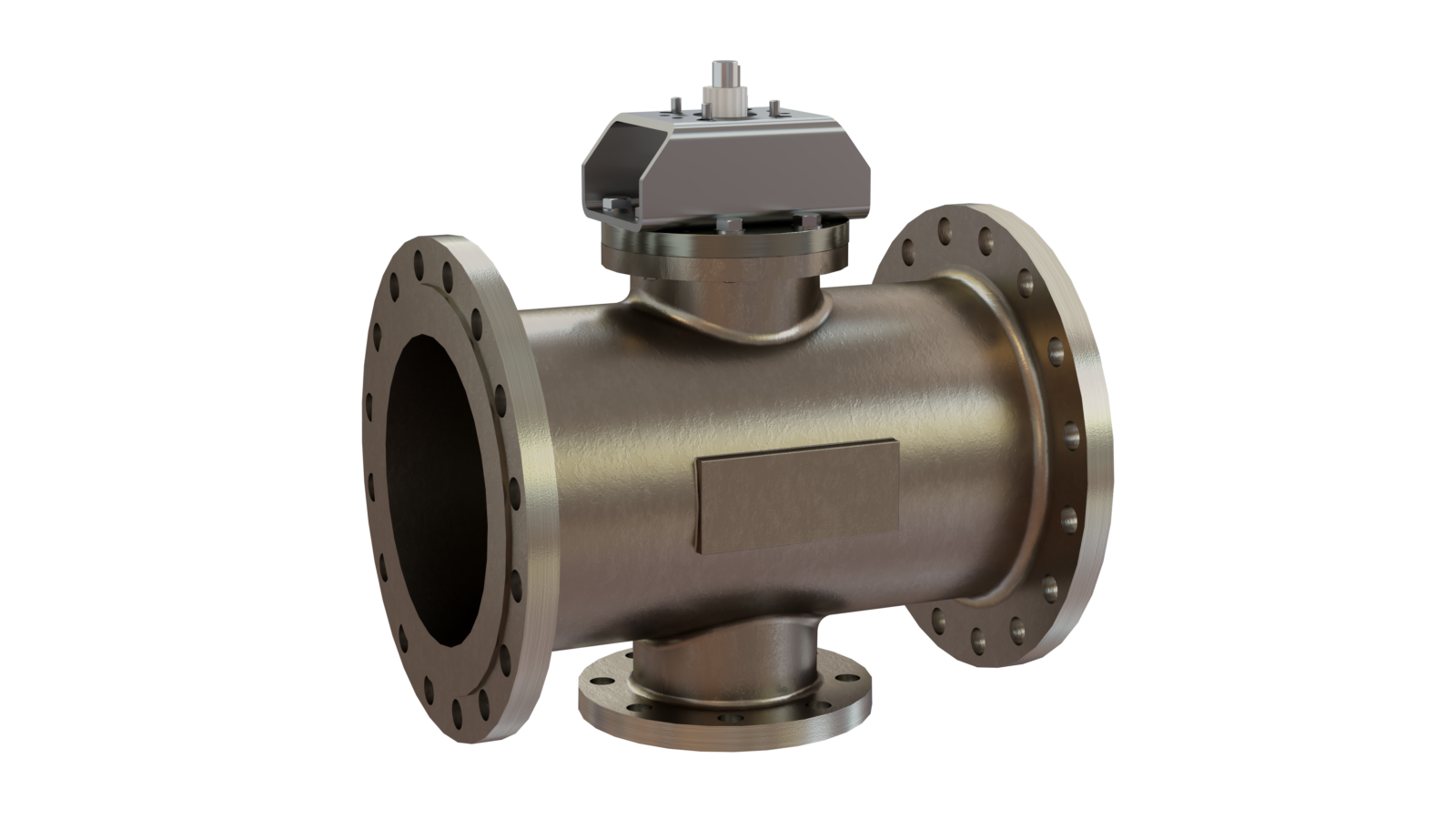

Solaris®

Perfect for viscous slurries, the Solaris® heater features an optimized straight-through design and low shear flow. It is also perfect for heavy slurries with medium consistency or higher solid contents. The flow diffuser injects steam across the entire cross-section to ensure thorough mixing and a uniform temperature profile, even at a high volume and flow rate.

- Volume capability: 5 up to 25,000 gpm [1 up to 5,678 m³/hr]

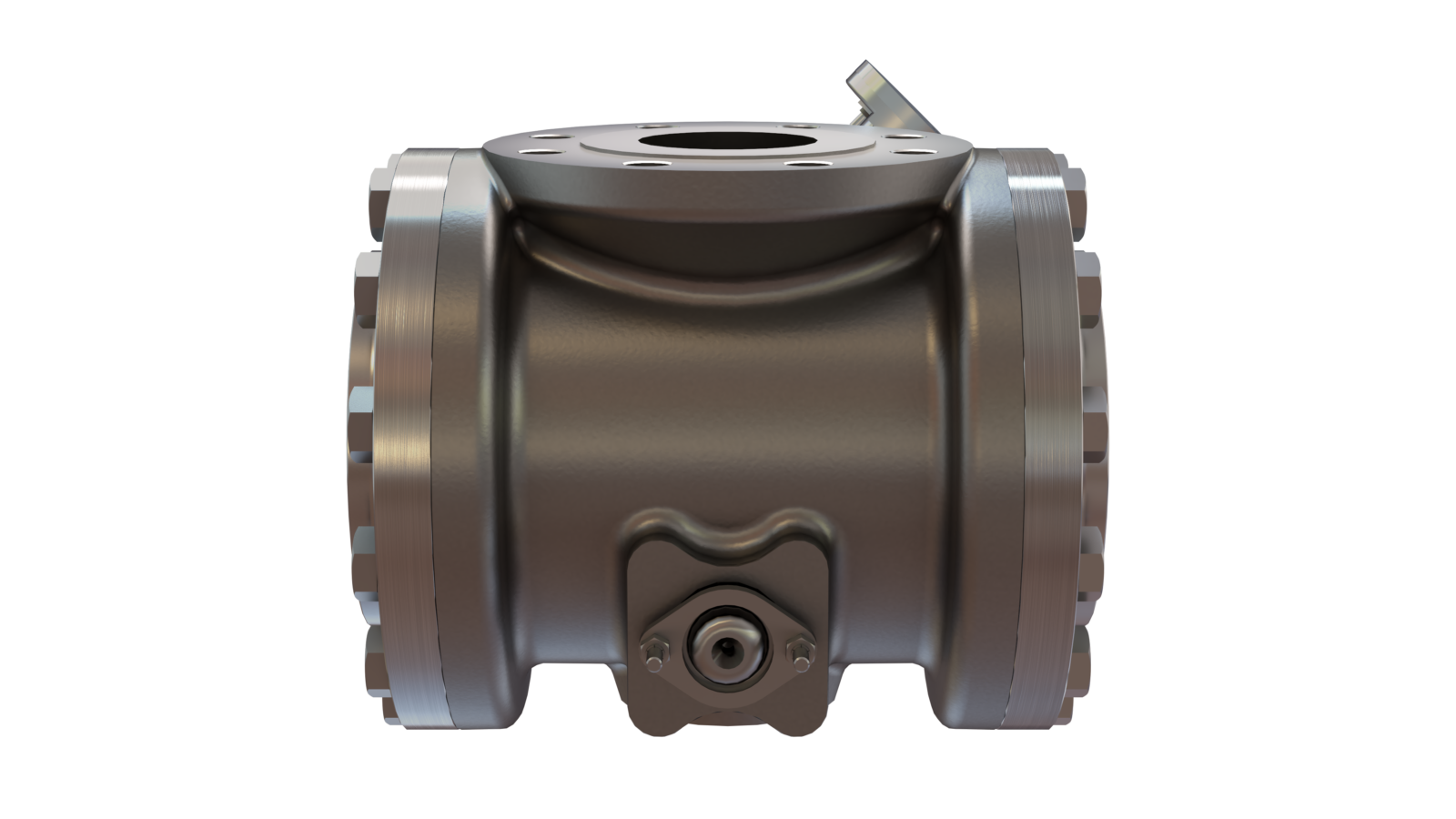

NOH™ (Non-Obstructing Heater)

The Non-Obstructing Heater is rugged enough to handle even the toughest abrasive materials, like sand and grit, to fibrous materials and large particulates.

- Its non-obstructive design protects against plugging, fouling, and pressure drop with its powerful, unrestricted flow.

- Volume capability: 30 up to 3,035 gpm [6.8 up to 689 m³/hr]