Overview

Syrup production presents challenges for ethanol plants striving to increase revenue through co-products. Achieving the ideal temperature for heating thin stillage or syrup is critical, as higher temperatures can act as an emulsifier to boost oil yield. Without accurate temperature control, plants may miss opportunities to enhance oil production or may rely heavily on costly emulsion breaker chemicals.

Direct Steam Injection (DSI) heaters deliver precise and consistent temperature control in syrup heating:

- Heating thin stillage or syrup beyond standard temperatures to meet minimum feed tag specifications

- Increasing syrup production and boosting overall revenue

- Accurate and consistent temperature control for more reliable operations

- Acting as an emulsifier, potentially reducing or eliminating the need for emulsion breaker chemicals

- Maintaining or increasing syrup and oil production efficiency with optimized heating solutions

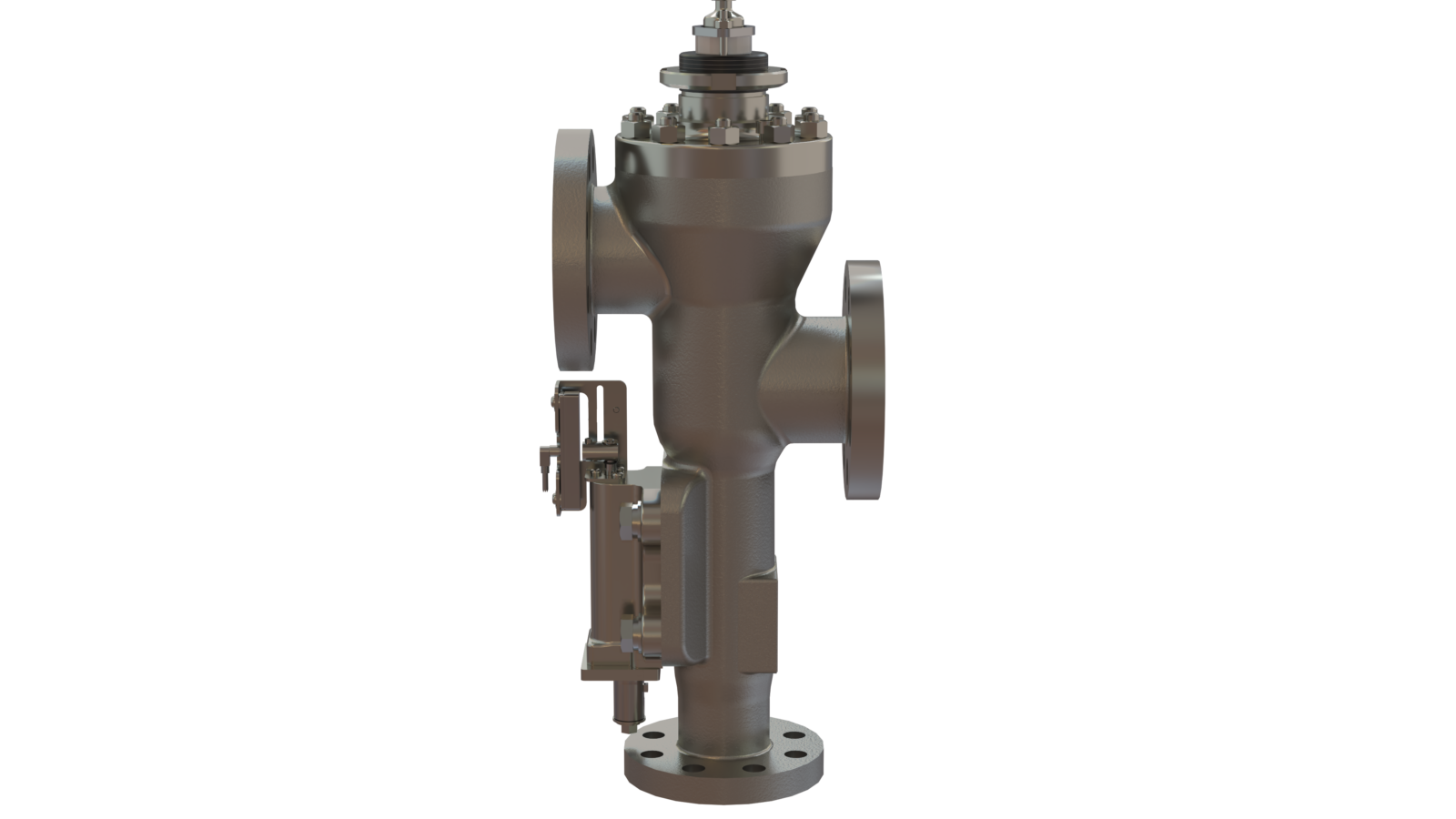

Hydroheater®

Also known as the Jetcooker™, our Hydroheater® has the longest proven history of heating and processing a complex range of liquids and materials. Known for its adjustability, durability, and power, the near century of engineering and innovation behind the design of this workhorse speaks for itself.

- Volume capability: 1 up to 6,700 gpm [0.2 up to 1,522 m³/hr]

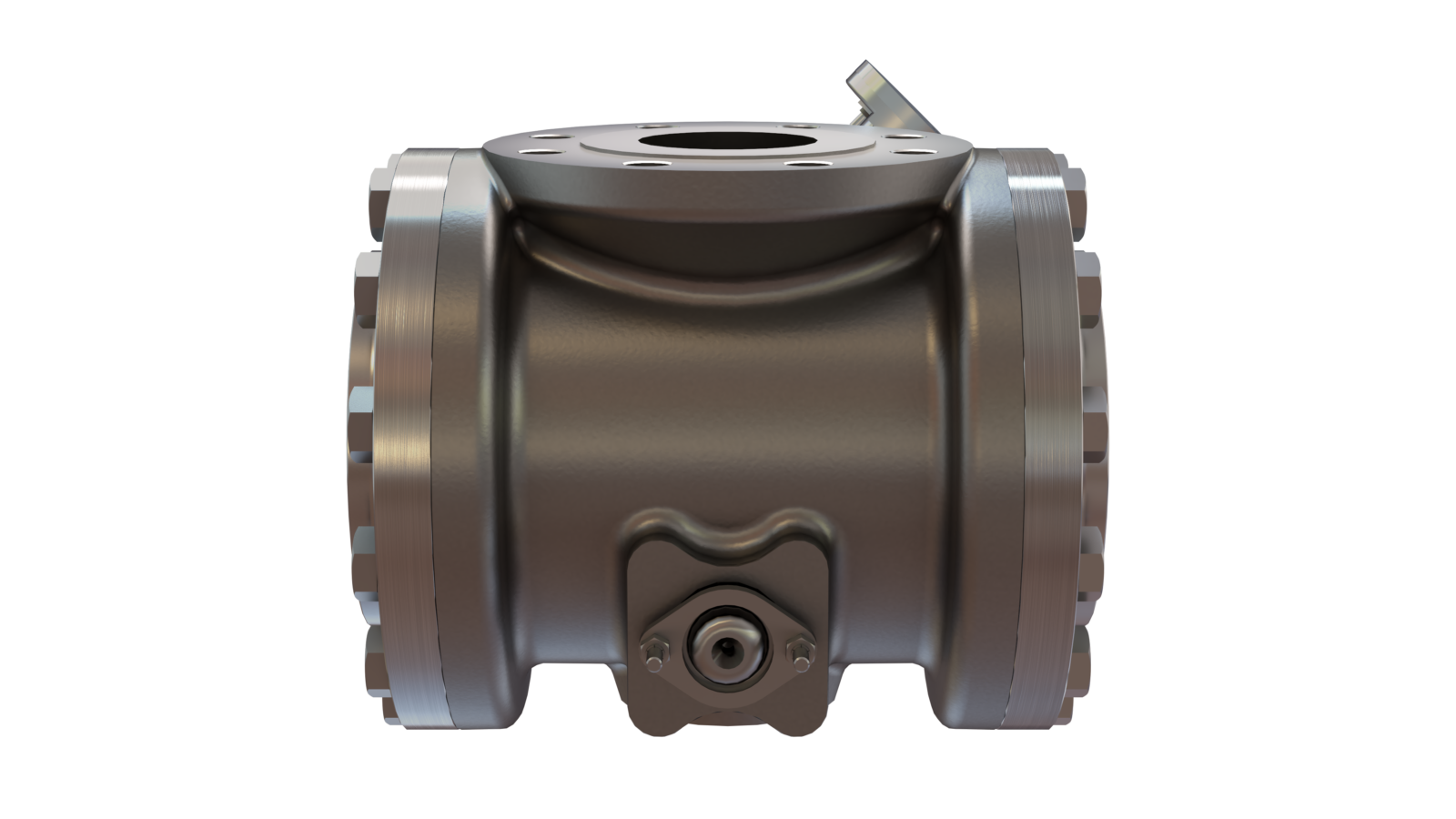

NOH™ (Non-Obstructing Heater)

The Non-Obstructing Heater is rugged enough to handle even the toughest abrasive materials, like sand and grit, to fibrous materials and large particulates.

- Its non-obstructive design protects against plugging, fouling, and pressure drop with its powerful, unrestricted flow.

- Volume capability: 30 up to 3,035 gpm [6.8 up to 689 m³/hr]

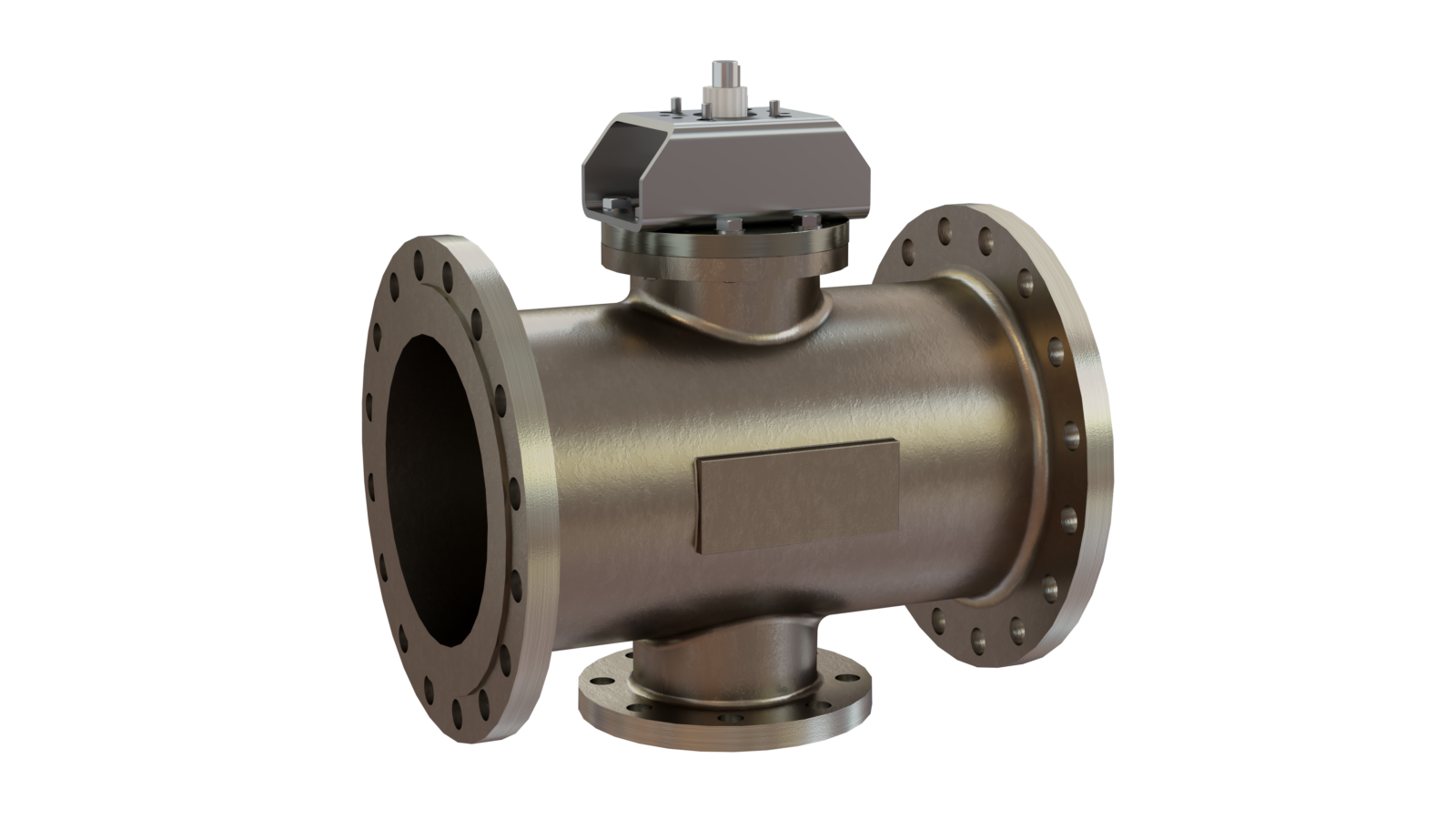

Solaris®

Perfect for viscous slurries, the Solaris® heater features an optimized straight-through design and low shear flow perfect for heavy slurries with medium consistency or higher solid contents. The flow diffuser injects steam across the entire cross-section to ensure thorough mixing and a uniform temperature profile even at a high volume and flow rate.

- Volume capability: 5 up to 25,000 gpm [1 up to 5,678 m³/hr]

EZ Heater®

The EZ Heater® is the industry leader in all hot water applications with its unique internal modulation, and self-cleaning ability. With on-demand hot water where you need it, the EZ Heater is ideal for washing stations, Clean in Place (CIP) systems, and anywhere reliable hot water is needed.

- Volume capability: 2 up to 1,350 gpm [.5 up to 306 m3/hr]