Overview

Steam sparging nozzles for slurry tank heating in ethanol plants may be the current industry standard but also has its disadvantages. High steam temperatures (up to 350°F) can damage starch and enzymes, uneven heat distribution from bottom-only steam injection leaves enzymes at suboptimal conditions, poor steam mixing causes cavitation, and uncondensed steam escapes, wasting energy and increasing costs.

Direct Steam Injection (DSI) heaters offer a highly effective slurry tank solution over sparging:

- Ensures higher quality starch conversion by preventing hot spots, optimizing enzyme utilization, and achieving consistent discharge temperature

- Maintains accurate temperature control, minimizing variations across the tank for optimized enzyme retention and starch conversion

- Reduces maintenance by containing steam injection externally, preventing damage to the slurry tank and spargers

- Saves energy by condensing all steam if used in the Hydroheater, minimizing steam loss and lowering boiler fuel usage

- Facilitates particle size reduction through added shear that breaks up “dough bars” and exposes more starch surface area and improving starch conversion

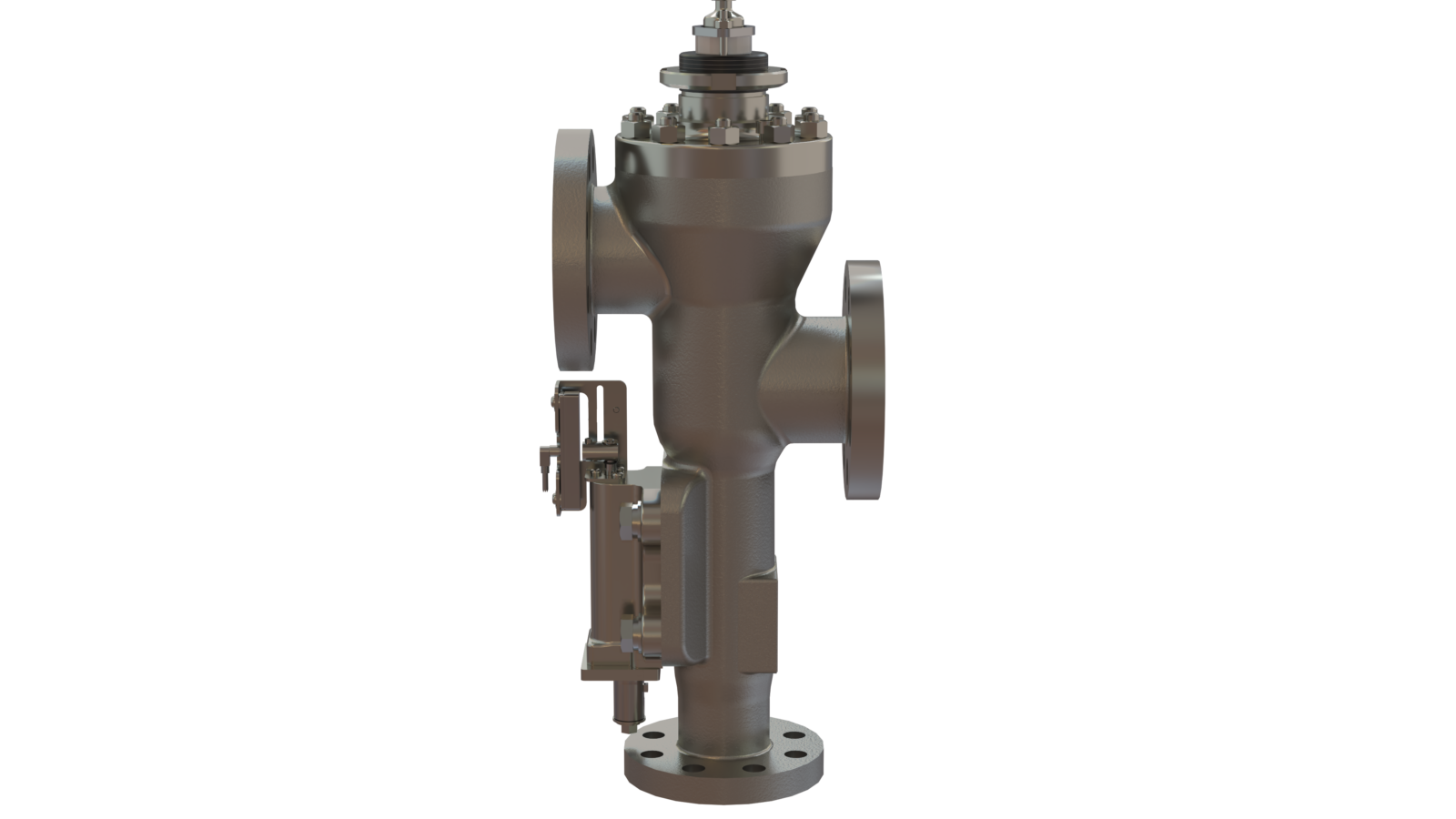

Hydroheater®

Also known as the Jetcooker™, our Hydroheater® has the longest proven history of heating and processing a complex range of liquids and materials. Known for its adjustability, durability, and power, the near century of engineering and innovation behind the design of this workhorse speaks for itself.

- Volume capability: 1 up to 6,700 gpm [0.2 up to 1,522 m³/hr]

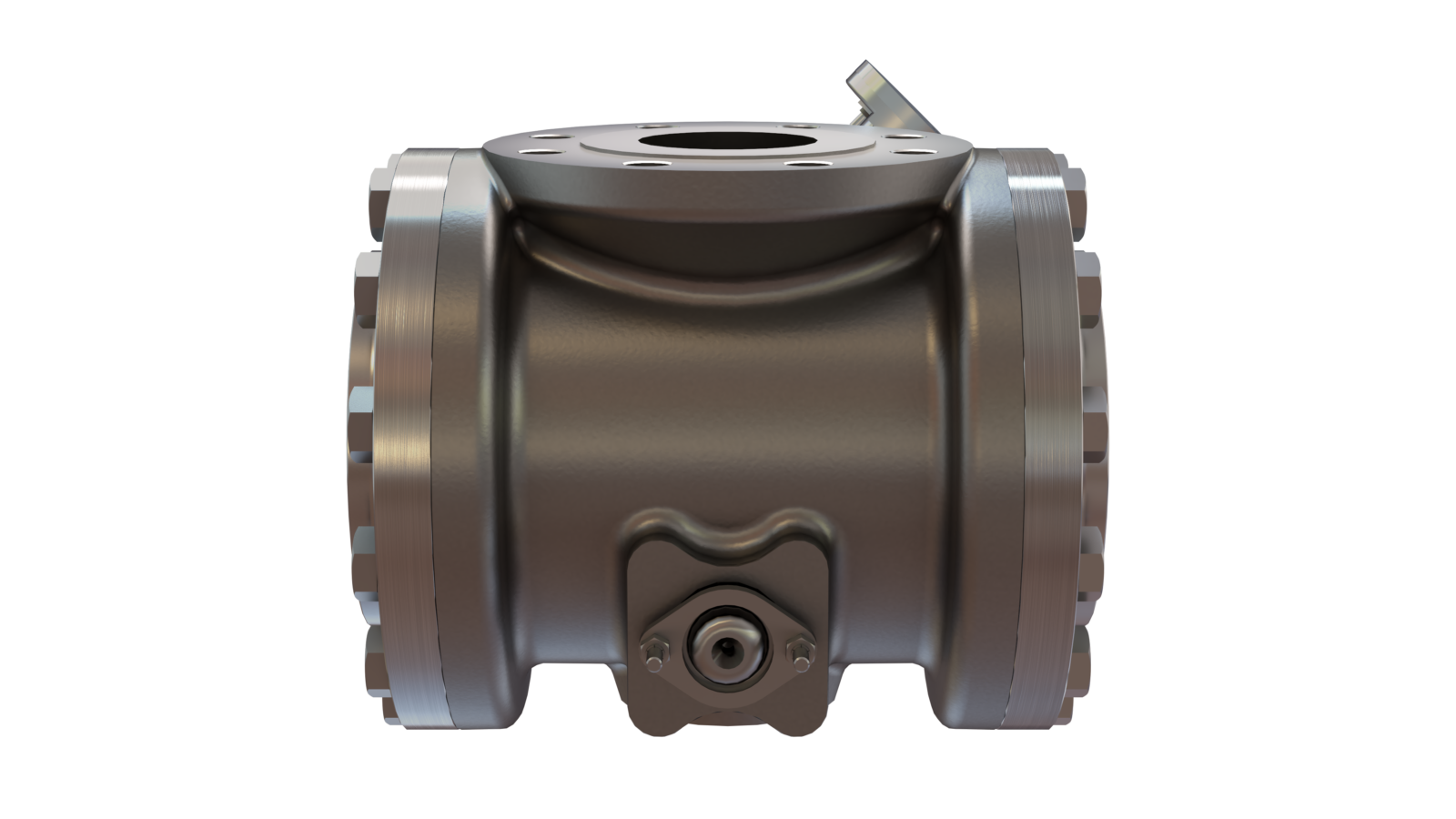

NOH™ (Non-Obstructing Heater)

The Non-Obstructing Heater is rugged enough to handle even the toughest abrasive materials, like sand and grit, to fibrous materials and large particulates.

- Its non-obstructive design protects against plugging, fouling, and pressure drop with its powerful, unrestricted flow.

- Volume capability: 30 up to 3,035 gpm [6.8 up to 689 m³/hr]

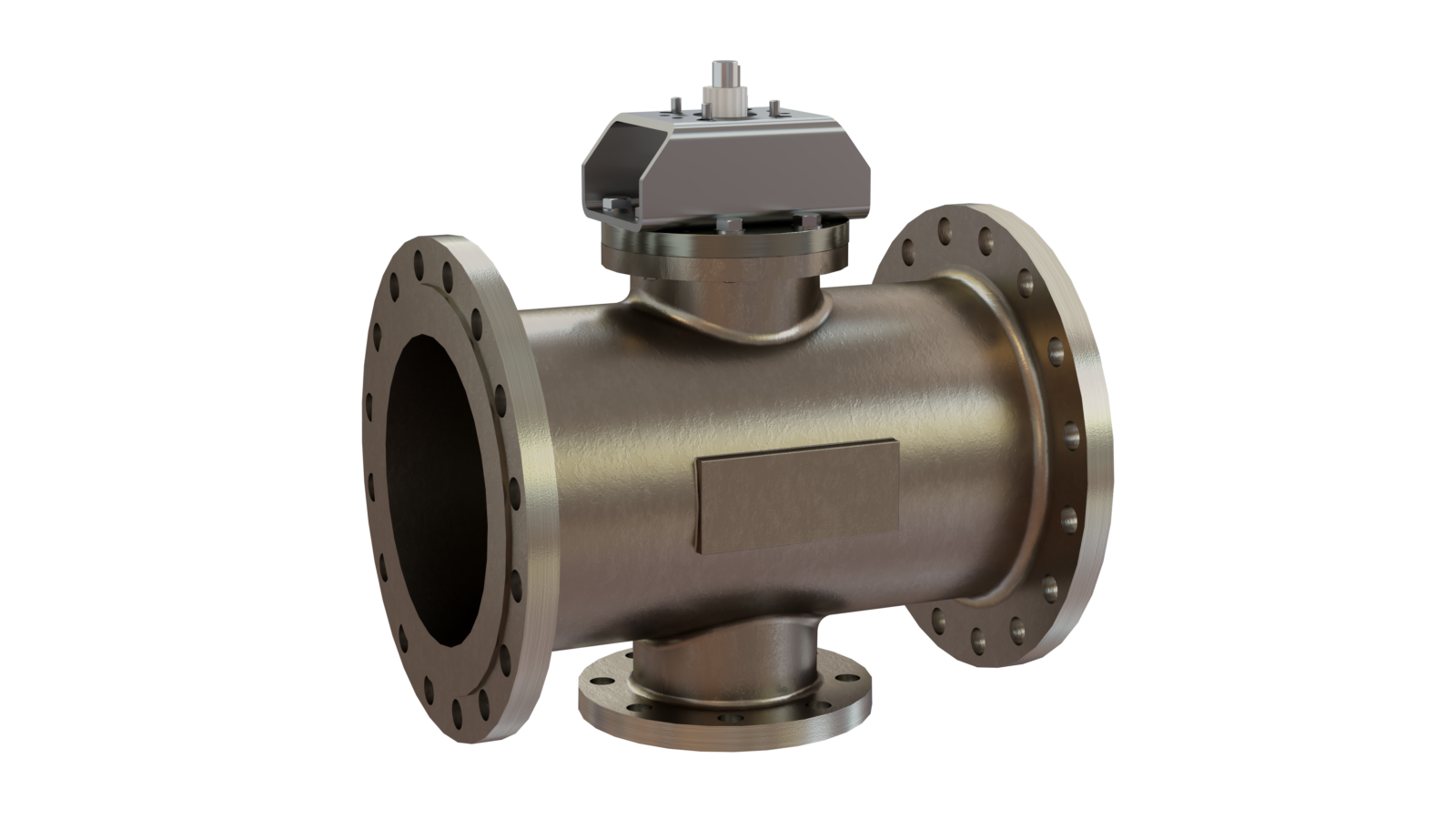

Solaris®

Perfect for viscous slurries, the Solaris® heater features an optimized straight-through design and low shear flow perfect for heavy slurries with medium consistency or higher solid contents. The flow diffuser injects steam across the entire cross-section to ensure thorough mixing and a uniform temperature profile even at a high volume and flow rate.

- Volume capability: 5 up to 25,000 gpm [1 up to 5,678 m³/hr]

EZ Heater®

The EZ Heater® is the industry leader in all hot water applications with its unique internal modulation, and self-cleaning ability. With on-demand hot water where you need it, the EZ Heater is ideal for washing stations, Clean in Place (CIP) systems, and anywhere reliable hot water is needed.

- Volume capability: 2 up to 1,350 gpm [.5 up to 306 m3/hr]