Overview

In the personal care industry, precise and efficient heating is essential for manufacturing lotions, shampoos, conditioners, creams, and cleansers. Traditional heating systems, like sparging or indirect heat exchangers, can often be less efficient, resulting in inconsistent product quality, higher energy costs, and increased maintenance.

Direct Steam Injection (DSI) heaters provide a solution with on-demand, consistent, and precisely controlled heating to streamline production processes in personal care manufacturing:

- Ensures reliable compliance with GMP and FDA standards through precise temperature control and easy data logging for quality audits.

- Provides consistent, uniform heating for stable texture, viscosity, and product quality, ensuring active ingredients remain effective and enhancing product shelf life

- Enhances energy efficiency with nearly 100% thermal transfer, reducing energy costs and supporting sustainability in large-scale production

- Ensures improved emulsification and texture control with precise temperature management, stabilizing emulsions for smooth, uniform products

- Increases throughput with on-demand heating, minimizing processing time and allowing flexibility to meet demand in a competitive market

- Reduces maintenance needs due to a compact design, fewer moving parts, and lower risk of scaling, supporting continuous production and reducing downtime

- Boosts sanitation with direct steam injection, minimizing contamination risks and supporting compliance with hygiene standards

- Adapts to a range of personal care applications, enabling precise heating across diverse products like lotions, shampoos, and creams, facilitating efficient production scaling

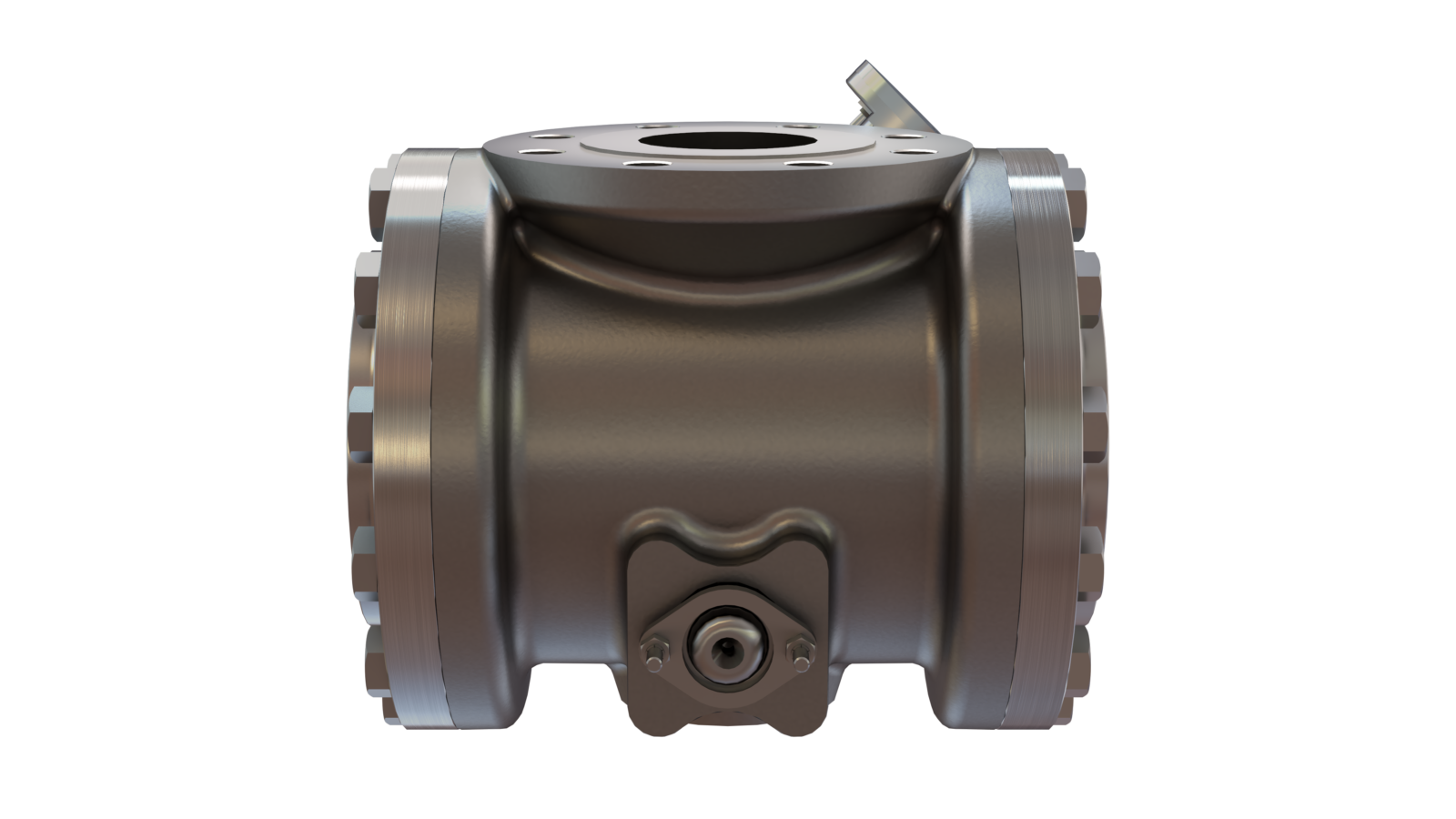

NOH™ (Non-Obstructing Heater)

The Non-Obstructing Heater is rugged enough to handle even the toughest abrasive materials, like sand and grit, to fibrous materials and large particulates.

- Its non-obstructive design protects against plugging, fouling, and pressure drop with its powerful, unrestricted flow.

- Volume capability: 30 up to 3,035 gpm [6.8 up to 689 m³/hr]

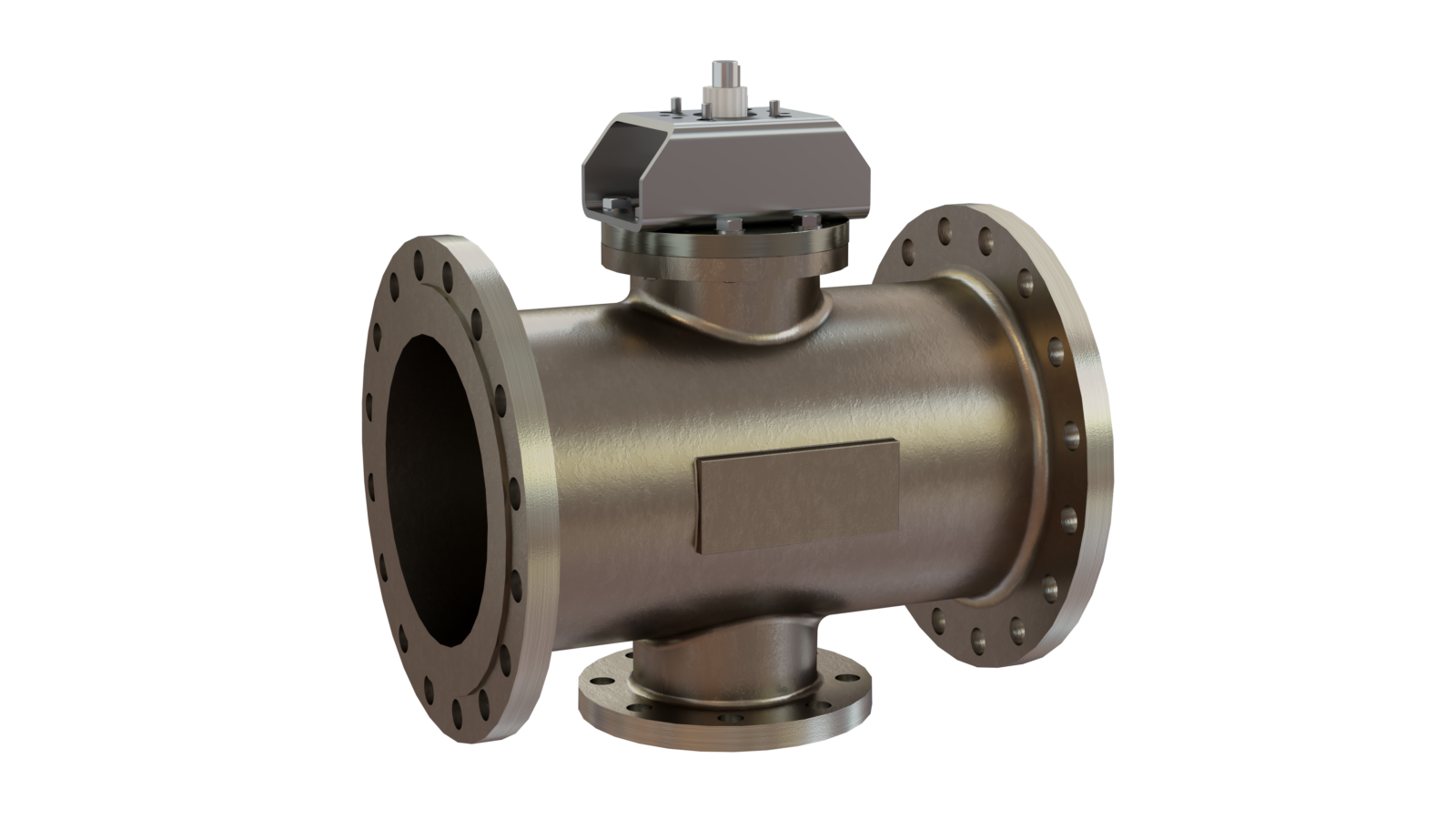

Solaris®

Perfect for viscous slurries, the Solaris® heater features an optimized straight-through design and low shear flow perfect for heavy slurries with medium consistency or higher solid contents. The flow diffuser injects steam across the entire cross-section to ensure thorough mixing and a uniform temperature profile even at a high volume and flow rate.

- Volume capability: 5 up to 25,000 gpm [1 up to 5,678 m³/hr]

Hydron™

The Hydron™ 400 Series is the most precise, accurate, versatile Sanitary Hydroheater. Its modular 3-A-certified design delivers optimal process flexibility and stability in an easy-to-use and maintain design.

- Volume capability: 1 up to 460 gpm [0.2 up to104.5 m³/hr]

EZ Heater®

The EZ Heater® is the industry leader in all hot water applications with its unique internal modulation, and self-cleaning ability. With on-demand hot water where you need it, the EZ Heater is ideal for washing stations, Clean in Place (CIP) systems, and anywhere reliable hot water is needed.

- Volume capability: 2 up to 1,350 gpm [.5 up to 306 m3/hr]