Overview

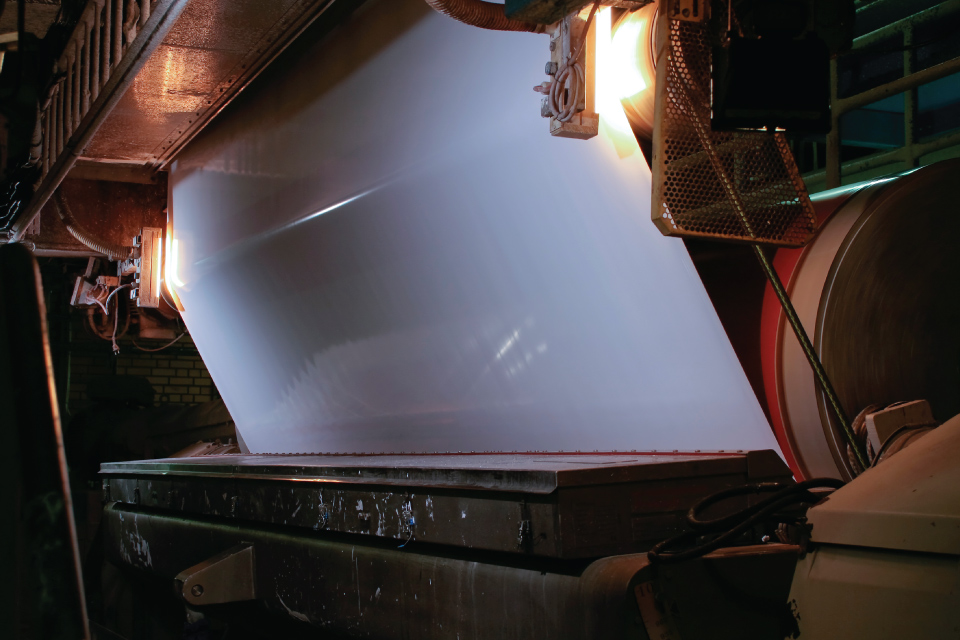

In the kraft pulping process, green liquor is critical in recovering chemicals used to produce paper. Efficient heating of green liquor is essential for maintaining process efficiency and reducing energy consumption.

Direct Steam Injection (DSI) heaters offer several advantages over traditional heating methods in green liquor processing:

- Fast and even heating, preventing both hotspots and cold zones and leading to efficient conversion into white liquor and consistent processing throughout the batch

- By minimizing heat transfer losses and reducing energy consumption, DSI heaters optimize energy use, contributing to lower operational costs and supporting environmental sustainability

- Real-time temperature adjustments help ensure green liquor is heated to the optimal temperature for chemical reactions

- Reduced risk of scaling and fouling, minimizing maintenance needs and ensuring more reliable operation with less downtime

- Smaller footprint compared to traditional systems, making them easier to integrate into existing paper mill operations while optimizing space and reducing installation costs

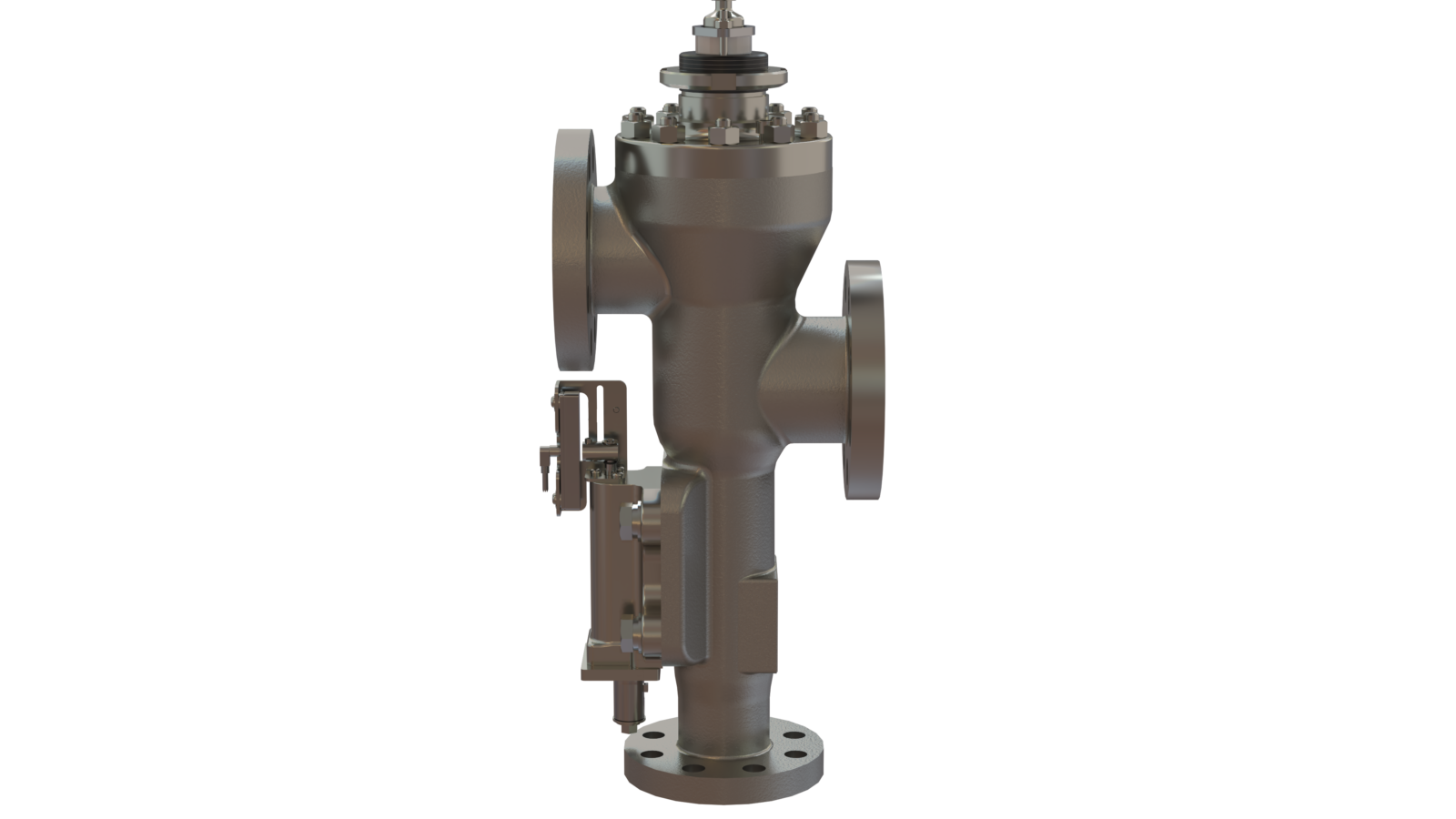

Hydroheater®

Also known as the Jetcooker™, our Hydroheater® has the longest proven history of heating and processing a complex range of liquids and materials. Known for its adjustability, durability, and power, the near century of engineering and innovation behind the design of this workhorse speaks for itself.

- Volume capability: 1 up to 6,700 gpm [0.2 up to 1,522 m³/hr]