Overview

Black liquor, a by-product of the kraft pulping process, is crucial in recovering chemicals and generating energy within paper mills. Efficient heating is essential for black liquor processing, particularly in concentration, combustion, and chemical recovery stages.

Direct Steam Injection (DSI) heaters offer numerous advantages over traditional heating methods, improving the overall efficiency, energy usage, and performance in handling black liquor:

- Delivers on-demand and uniform heating, preventing localized overheating and ensuring consistent temperature control in black liquor processing

- Increases energy efficiency by directly transferring thermal energy, reducing heat loss and operational costs

- Enhances evaporation rates and solids concentration, improving recovery boiler performance and maximizing energy recovery

- Reduces fouling and scaling by eliminating contact with large heat transfer surfaces, minimizing maintenance downtime

- Offers a compact design for easy integration into existing mill layouts, optimizing space and simplifying installation

- Provides precise temperature control, supporting efficient chemical recovery, and minimizing waste

- Improves safety by lowering pressure system risks and contributing to better environmental compliance through reduced emissions

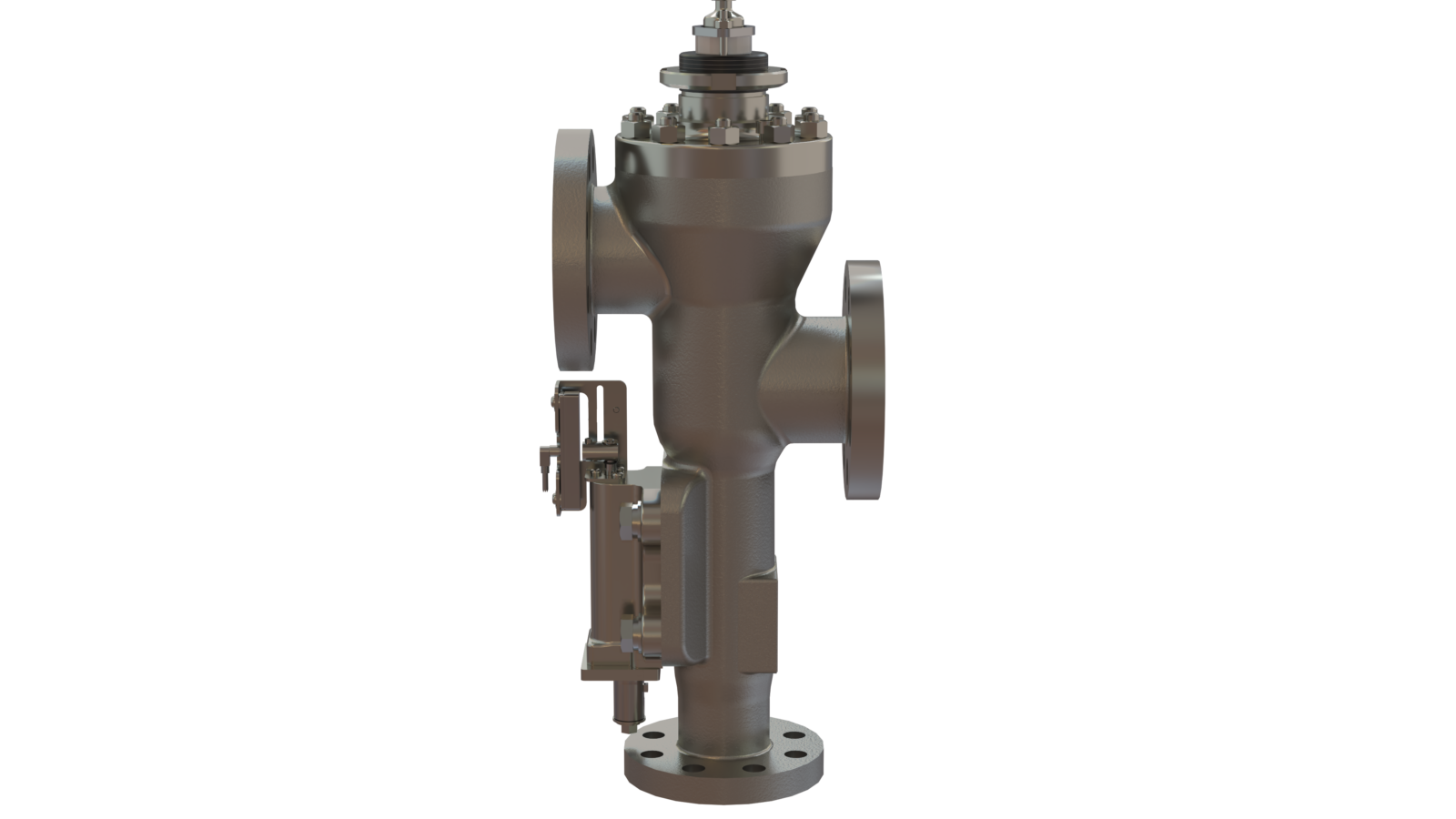

Hydroheater®

Also known as the Jetcooker™, our Hydroheater® has the longest proven history of heating and processing a complex range of liquids and materials. Known for its adjustability, durability, and power, the near century of engineering and innovation behind the design of this workhorse speaks for itself.

- Volume capability: 1 up to 6,700 gpm [0.2 up to 1,522 m³/hr]