Overview

Tomato processing requires careful temperature control to maintain product quality, preserve nutrients, and achieve the ideal consistency. From sauces and pastes to purees and juices, heating is crucial in tomato processing.

Direct Steam Injection heaters offer on-demand, efficient, and precise heating, providing numerous advantages over traditional heating systems in tomato-based product production:

- Provides on-demand heating to preserve tomatoes’ vibrant color, fresh flavor, and nutritional value, minimizing exposure and enhancing product appeal.

- Ensures consistent, even heating for uniform texture, reducing hot and cold spots, preventing burn-on, and improving quality across sauces, pastes, and purees—even with high-viscosity products.

- Increases energy efficiency with nearly 100% thermal transfer, using direct steam injection to reduce energy costs and support sustainability.

- Maintains consistent viscosity and thickness, enabling precise temperature control to achieve desired consistency without additional thickeners.

- Reduces fouling and maintenance through direct steam injection, minimizing scaling and extending equipment lifespan, resulting in less downtime.

- Supports food safety compliance with sanitary heating, eliminating intermediary surfaces where contaminants could accumulate.

- Adapts to varying production volumes, offering scalability for both large-scale and specialty tomato processing runs, enhancing production flexibility.

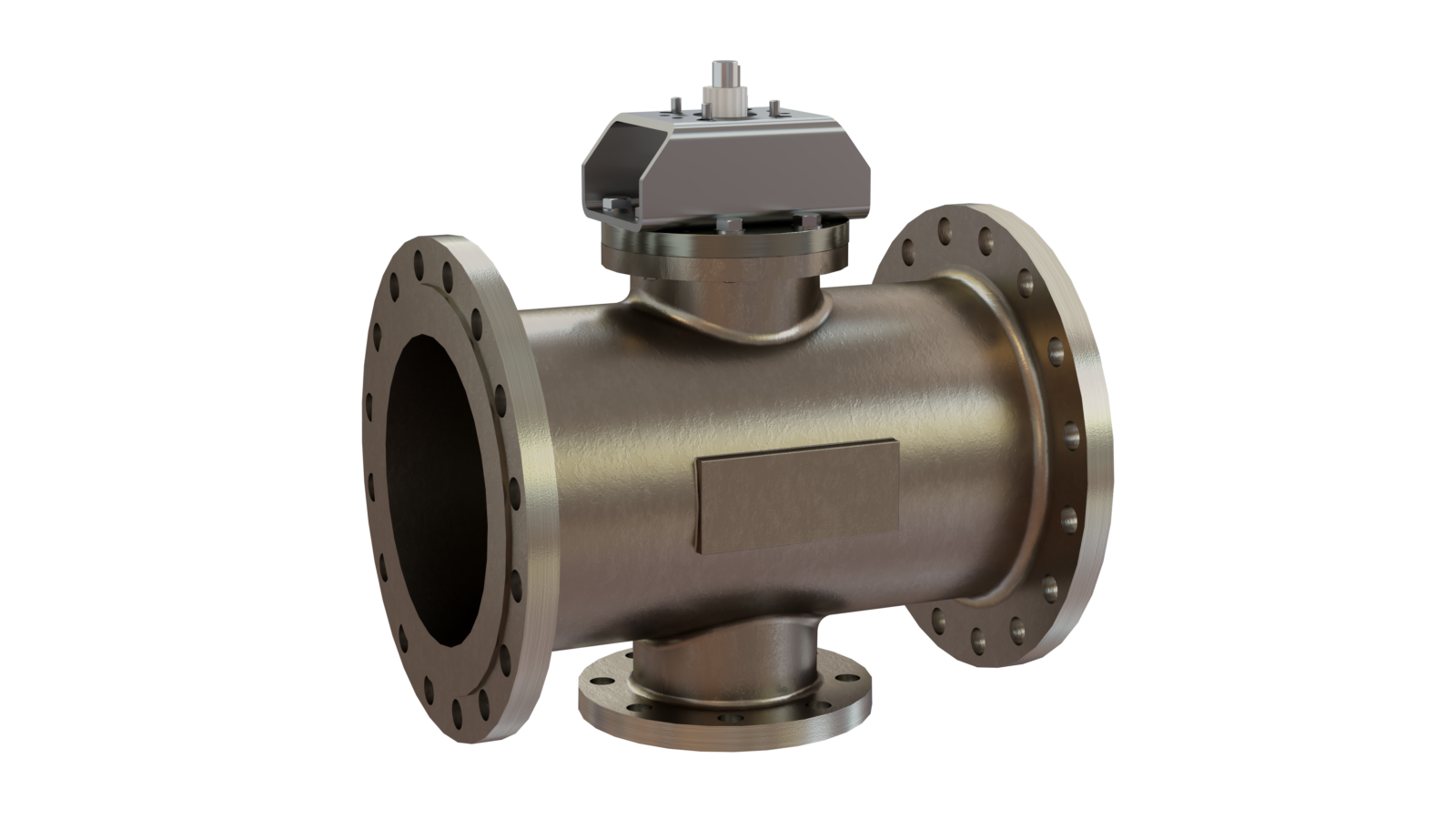

Solaris®

Perfect for viscous slurries, the Solaris® heater features an optimized straight-through design and low shear flow. It is also perfect for heavy slurries with medium consistency or higher solid contents. The flow diffuser injects steam across the entire cross-section to ensure thorough mixing and a uniform temperature profile, even at a high volume and flow rate.

- Volume capability: 5 up to 25,000 gpm [1 up to 5,678 m³/hr]

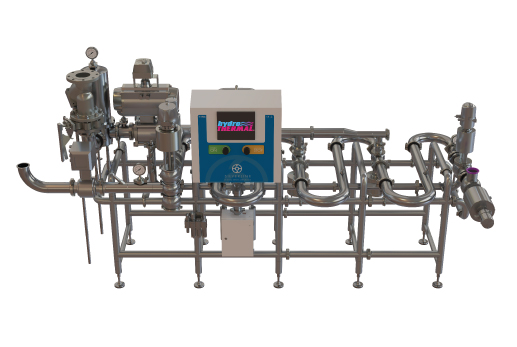

Infuze™

Compact and fully sanitary cooking skid that helps products achieve finished recipe results, pasteurization, or blended emulsification through 3-A, EHEDG, and FDA certifications.

- Volume capability: 3 up to 255 gpm [0.7 up to 57.9 m3/hr]

Silverline™

The Silverline™ is a polished stainless-steel steel system engineered to replicate specified processing profiles precisely. It is 3-A certified and meets EHEDG, CE, and FDA requirements. Despite its simple appearance, it incorporates thousands of hours of engineering into a single, advanced machine – acclaimed as one of the most advanced food and beverage processing systems globally.

- Volume capability: 5 up to 200 gpm [1.1 up to 45 m3/hr]

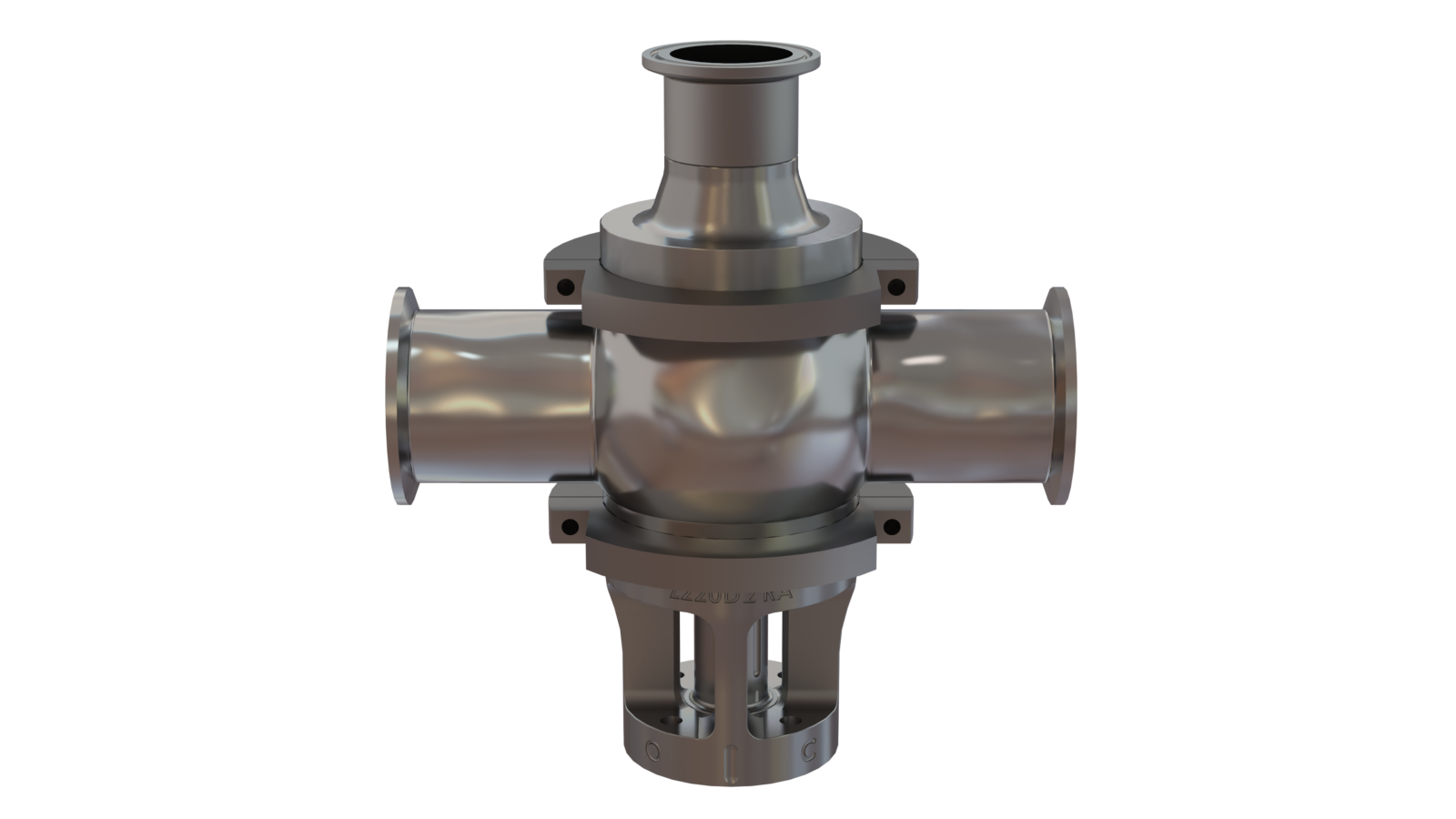

Hydron™

The Hydron™ 400 Series is the most precise, accurate, versatile Sanitary Hydroheater. Its modular 3-A-certified design delivers optimal process flexibility and stability in an easy-to-use and maintain design.

- Volume capability: 1 up to 460 gpm [0.2 up to104.5 m³/hr]

EZ Heater®

The EZ Heater® is the industry leader in all hot water applications with its unique internal modulation, and self-cleaning ability. With on-demand hot water where you need it, the EZ Heater is ideal for washing stations, Clean in Place (CIP) systems, and anywhere reliable hot water is needed.

- Volume capability: 2 up to 1,350 gpm [.5 up to 306 m3/hr]