Overview

Canning manufacturers need a consistent, efficient, and safe heating process in this demanding sector, whether preserving fruits, vegetables, soups, sauces, or proteins. Ensuring product quality and safety requires precise temperature control, on-demand heating, and reliable pasteurization or sterilization.

Direct Steam Injection (DSI) heaters provide several advantages over traditional heating methods, making them an ideal choice for modern canning operations:

- Rapid heating with DSI technology improves efficiency by bringing canned goods to the correct temperature quickly, preserving texture, flavor, and nutritional value

- Provides precise temperature control for food safety, ensuring uniform heating and eliminating cold spots, reducing the risk of spoilage or foodborne illness

- Increases energy efficiency by directly injecting steam into the product, reducing energy consumption and operational costs, supporting sustainable production

- Reduces equipment size and maintenance needs with a compact design and fewer moving parts, optimizing space and minimizing downtime in canning facilities

- Offers versatility to handle a wide range of canned products, from simple fruits to complex meals, with consistent and quick heating for various food types

- Ensures consistent product quality, by delivering reliable textures, flavors, and safety standards, helping to maintain customer satisfaction and brand loyalty

EZ Heater®

The EZ Heater® is the industry leader in all hot water applications with its unique internal modulation and self-cleaning ability. With on-demand hot water where you need it, the EZ Heater is ideal for washing stations, Clean in Place (CIP) systems, and anywhere reliable hot water is needed.

- Volume capability: 2 up to 1,350 gpm [.5 up to 306 m3/hr]

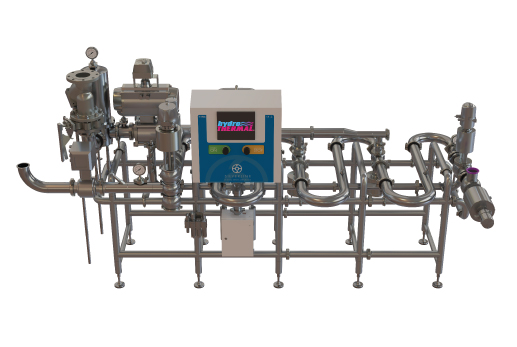

Infuze

Compact and fully sanitary cooking skid that helps products achieve finished recipe results, pasteurization, or blended emulsification through 3-A, EHEDG, and FDA certifications.

- Volume capability: 3 up to 255 gpm [0.7 up to 57.9 m3/hr]

Silverline™

The Silverline™ is a polished stainless-steel steel system engineered to replicate specified processing profiles precisely. It is 3-A certified and meets EHEDG, CE, and FDA requirements. Despite its simple appearance, it incorporates thousands of hours of engineering into a single, advanced machine – acclaimed as one of the most advanced food and beverage processing systems globally.

- Volume capability: 5 up to 200 gpm [1.1 up to 45 m3/hr]

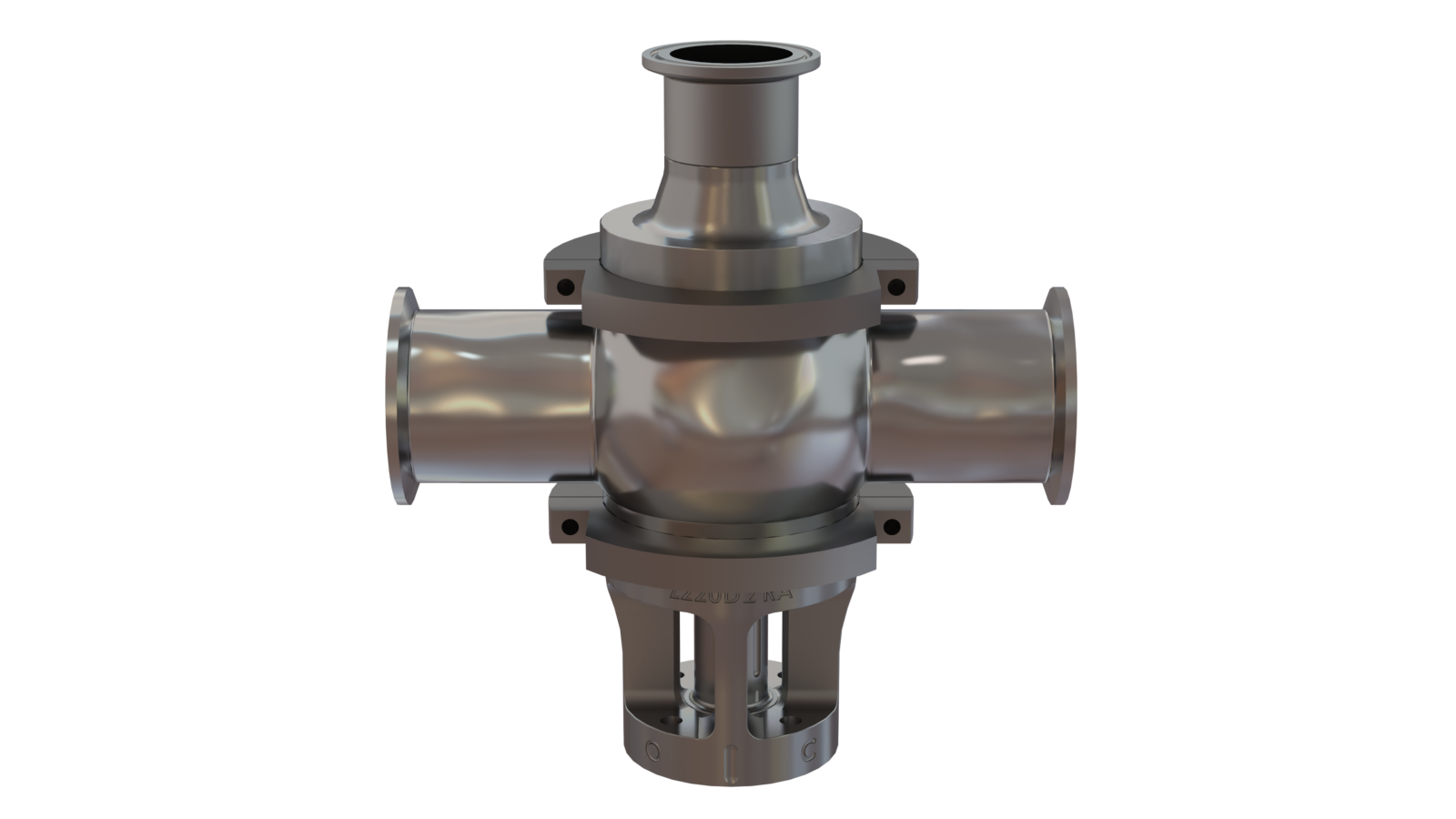

Hydron™

The Hydron™ 400 Series is the most precise, accurate, versatile Sanitary Hydroheater. Its modular 3-A-certified design delivers optimal process flexibility and stability in an easy-to-use and maintain design.

- Volume capability: 1 up to 460 gpm [0.2 up to104.5 m³/hr]