Overview

Fermentation, a critical process in the dairy industry, is essential for producing various fermented dairy products such as yogurt, kefir, and cheese. This process involves controlling temperature and time to create the optimal environment for beneficial (desired) bacteria to grow and develop the desired flavors and textures.

Direct Steam Injection heaters offer several key advantages over traditional heating methods in dairy fermentation, enhancing both the efficiency and quality of the fermentation process:

- Provides on-demand, uniform heating to reach fermentation temperatures quickly and evenly, creating an ideal environment for beneficial bacteria

- Preserves bacterial culture viability by minimizing heat exposure, preventing overheating that could harm essential cultures

- Enhances energy efficiency through direct steam injection, reducing heat loss and lowering energy costs while supporting sustainability goals

- Offers a compact design, reducing equipment footprint and simplifying maintenance, optimizing production space, and minimizing downtime

- Provides versatility for processing different fermented dairy products, with adjustable steam settings to meet specific fermentation needs

- Ensures consistent flavor, texture, and product quality through uniform heating, helping maintain high standards across batches and fostering brand loyalty

Infuze

Compact and fully sanitary cooking skid that helps products achieve finished recipe results, pasteurization, or blended emulsification through 3-A, EHEDG, and FDA certifications.

- Volume capability: 3 up to 255 gpm [0.7 up to 57.9 m3/hr]

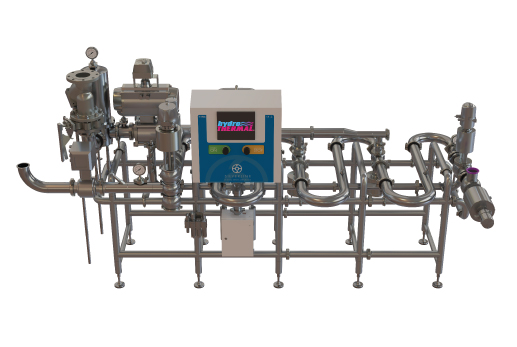

Silverline™

The Silverline™ is a polished stainless-steel steel system engineered to replicate specified processing profiles precisely. It is 3-A certified and meets EHEDG, CE, and FDA requirements. Despite its simple appearance, it incorporates thousands of hours of engineering into a single, advanced machine – acclaimed as one of the most advanced food and beverage processing systems globally.

- Volume capability: 5 up to 200 gpm [1.1 up to 45 m3/hr]

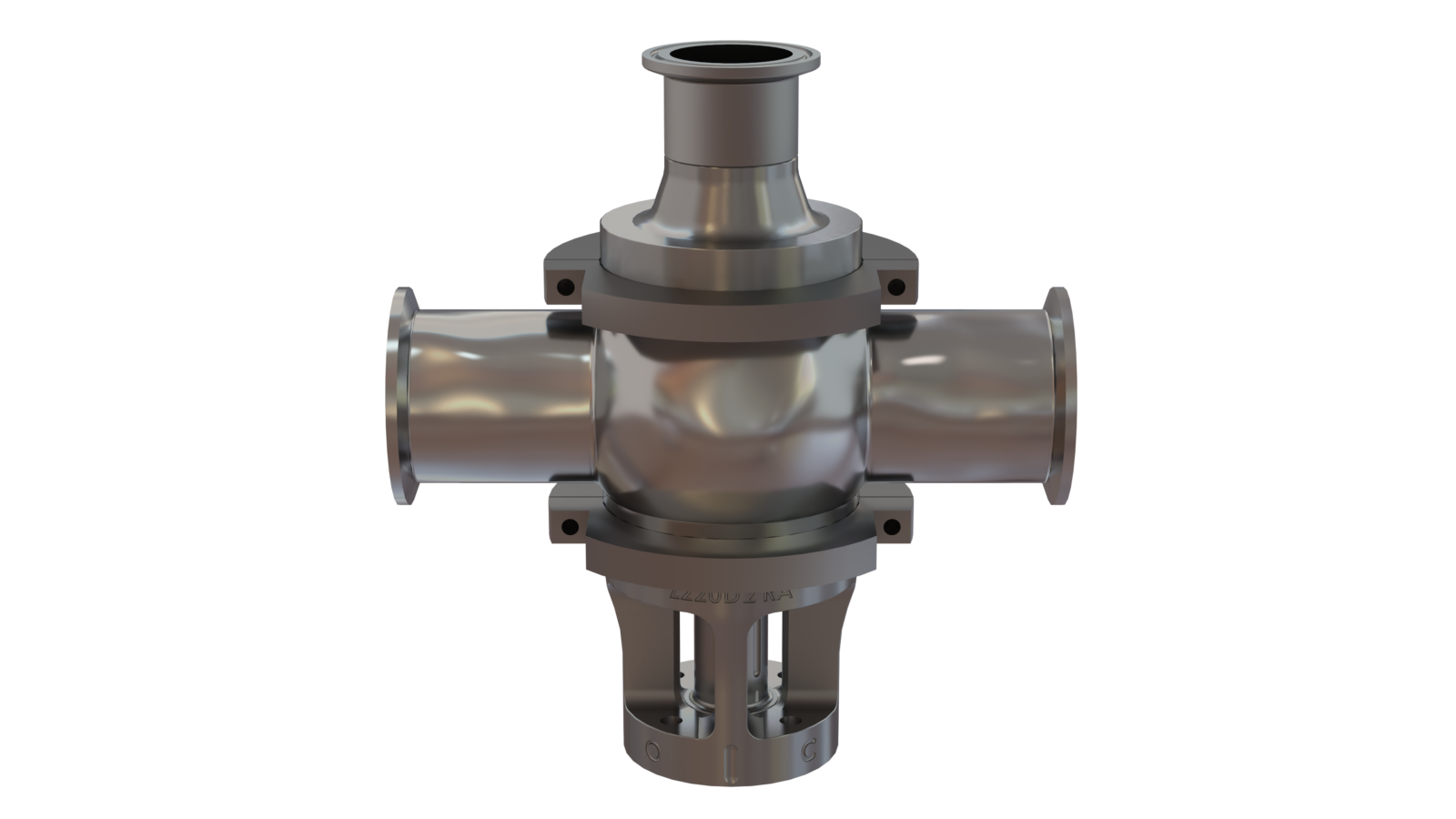

Hydron™

The Hydron™ 400 Series is the most precise, accurate, versatile Sanitary Hydroheater. Its modular 3-A-certified design delivers optimal process flexibility and stability in an easy-to-use and maintain design.

- Volume capability: 1 up to 460 gpm [0.2 up to104.5 m³/hr]

EZ Heater®

The EZ Heater® is the industry leader in all hot water applications with its unique internal modulation and self-cleaning ability. With on-demand hot water where you need it, the EZ Heater is ideal for washing stations, Clean in Place (CIP) systems, and anywhere reliable hot water is needed.

- Volume capability: 2 up to 1,350 gpm [.5 up to 306 m3/hr]