Overview

Controlling temperature within a jacketed reactor in chemical manufacturing is crucial for safe and efficient processing. Jacketed reactors are widely used to regulate reactions, control viscosity, and enhance product quality across various applications, from pharmaceuticals to specialty chemicals.

Direct Steam Injection heaters provide a highly efficient and reliable solution for heating wash fluids in filter cleaning applications, offering significant advantages over traditional heating systems:

- Delivers immediate and consistent heating for effective filter washing, directly injecting steam to maintain target temperatures and ensure thorough cleaning

- Enhances energy efficiency with near 100% thermal transfer, reducing energy waste and lowering operational costs, which supports sustainable production practices

- Minimizes fouling and scaling risks by directly heating the wash fluid, reducing maintenance needs, downtime, and extending equipment lifespan for increased productivity

- Offers flexibility to adapt to varying wash cycles and flow rates, enabling efficient washing across different filter types and supporting diverse chemical processes

- Compact design facilitates easy integration, saving valuable floor space and simplifying installation, making DSI heaters suitable for new setups and retrofits

- Provides a safe and environmentally friendly heating solution by eliminating intermediary surfaces, reducing contamination risks, and supporting eco-friendly production goals

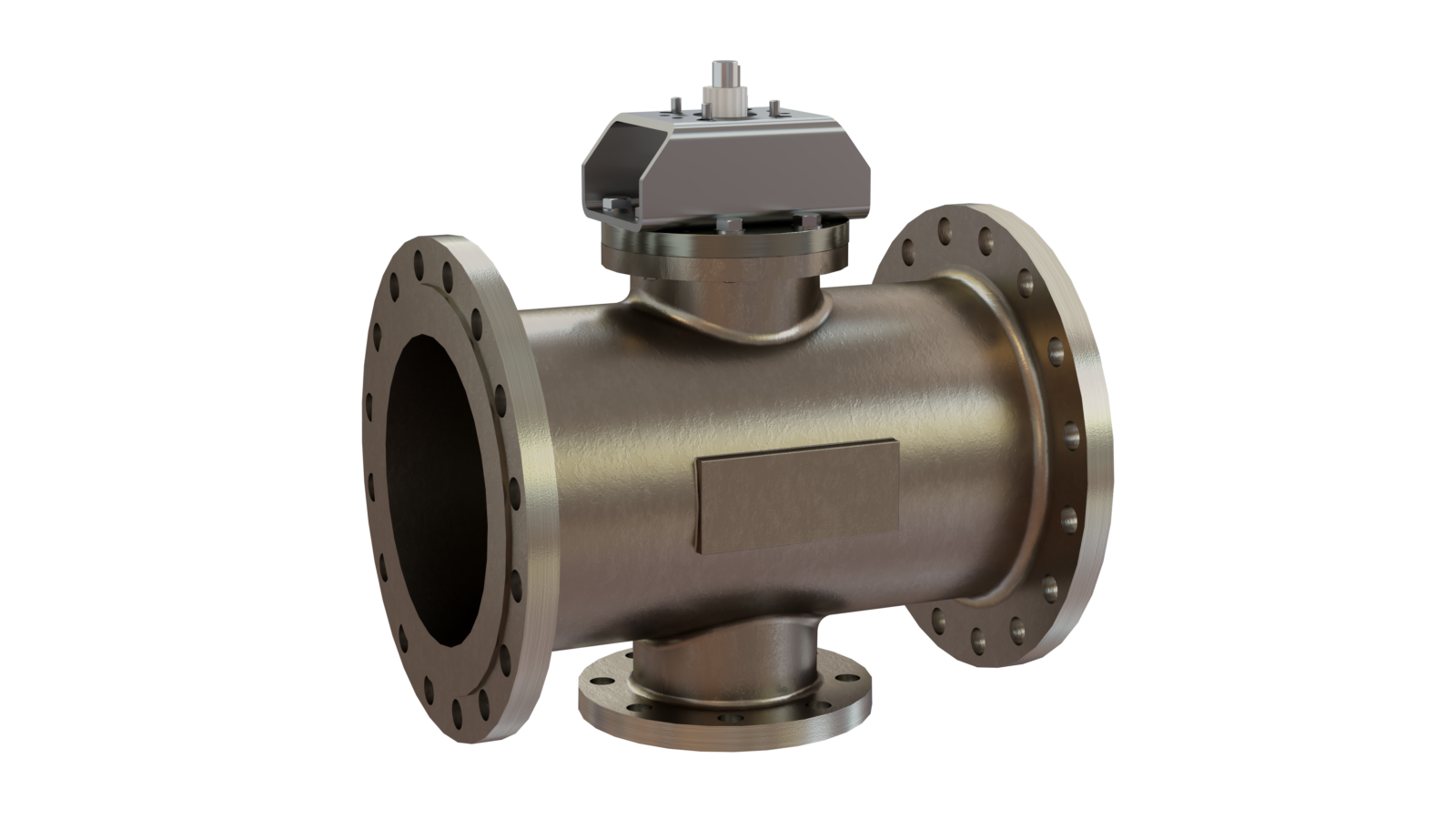

Hydroheater®

Also known as the Jetcooker™, our Hydroheater® has the longest proven history of heating and processing a complex range of liquids and materials. Known for its adjustability, durability, and power, the near century of engineering and innovation behind the design of this workhorse speaks for itself.

- Volume capability: 1 up to 6,700 gpm [0.2 up to 1,522 m³/hr]

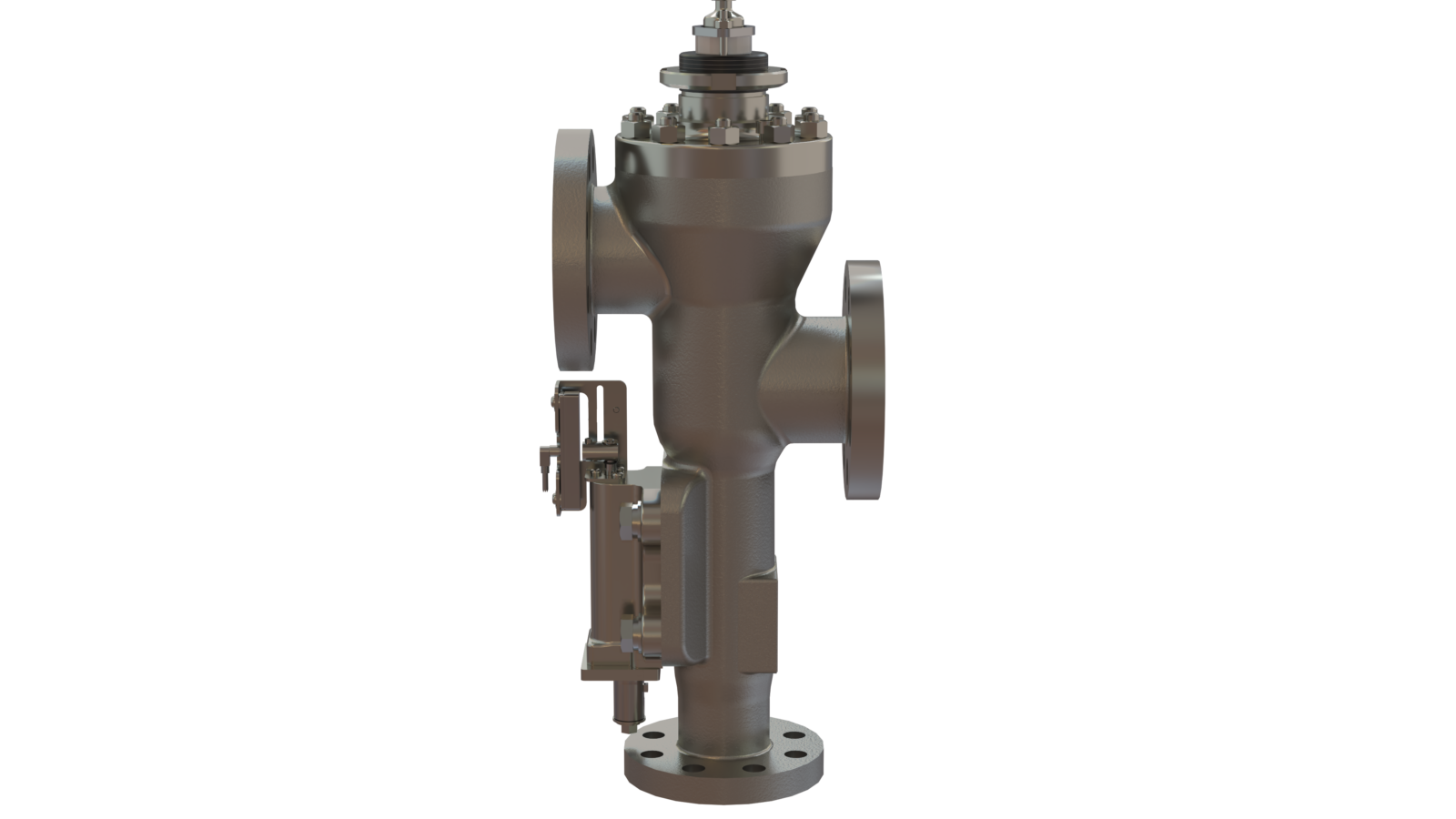

NOH™ (Non-Obstructing Heater)

The Non-Obstructing Heater is rugged enough to handle even the toughest abrasive materials, like sand and grit, to fibrous materials and large particulates.

- Its non-obstructive design protects against plugging, fouling, and pressure drop with its powerful, unrestricted flow.

- Volume capability: 30 up to 3,035 gpm [6.8 up to 689 m³/hr]

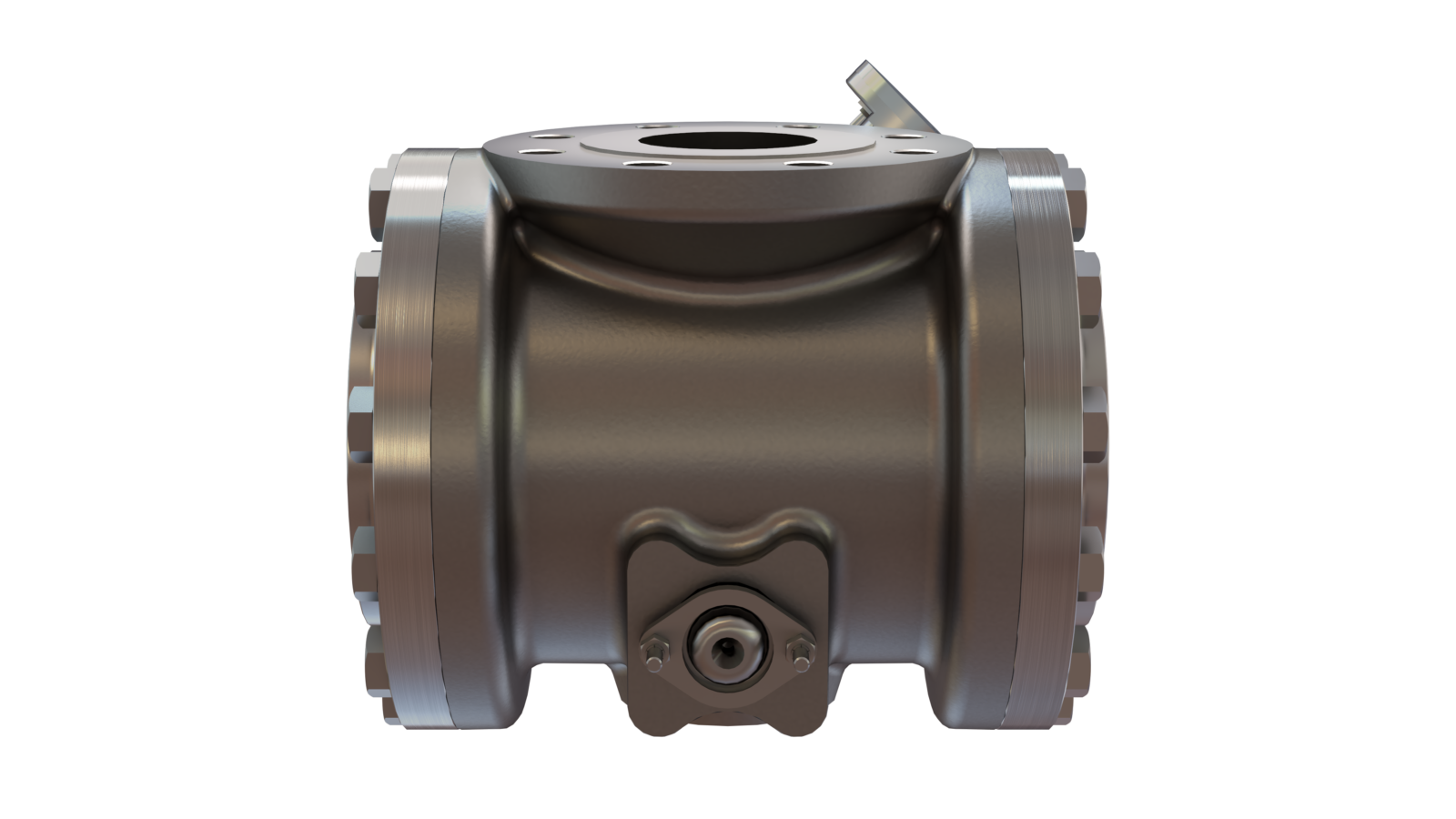

Solaris®

Perfect for viscous slurries, the Solaris® heater features an optimized straight-through design and low shear flow perfect for heavy slurries with medium consistency or higher solid contents. The flow diffuser injects steam across the entire cross-section to ensure thorough mixing and a uniform temperature profile even at a high volume and flow rate.

- Volume capability: 5 up to 25,000 gpm [1 up to 5,678 m³/hr]

EZ Heater®

The EZ Heater® is the industry leader in all hot water applications with its unique internal modulation, and self-cleaning ability. With on-demand hot water where you need it, the EZ Heater is ideal for washing stations, Clean in Place (CIP) systems, and anywhere reliable hot water is needed.

- Volume capability: 2 up to 1,350 gpm [.5 up to 306 m3/hr]