Overview

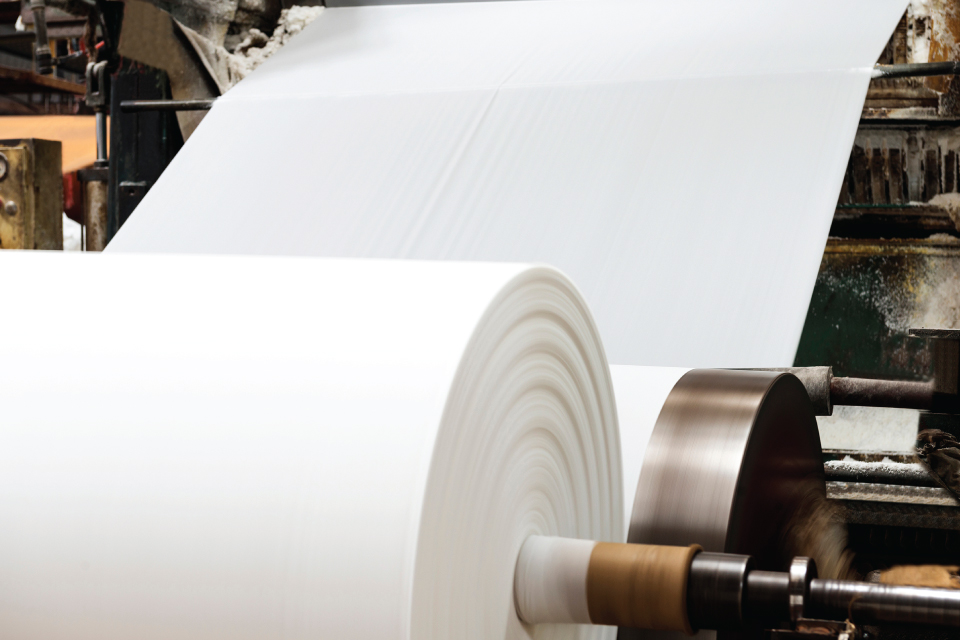

Tests have shown that detergent and microbicide dispersants are most effective when the shower water is about 122°F [50°C]. This is true whether the washing system is continuous or intermittent or whether felts are washed during shutdown periods. It’s essential that felts be kept as clean as possible to not only prolong their life but, more importantly, maintain paper machine production speeds and minimize downtime.

Direct Steam Injection (DSI) heaters offer numerous benefits in felt showers:

- The Hydroheater delivers heated water instantly without requiring warm-up or shutdown delays, ensuring cleaning schedules are not disrupted

- The system ensures that raw steam never contacts the felt, thanks to a flow switch and solenoid-operated valve that only allows steam flow when water is present

- Many paper mills have used this system for 10-15 years without significant maintenance or parts replacement, proving its durability

- High-velocity steam creates turbulence inside the system, which prevents scaling on internal surfaces, ensuring optimal performance over time

- Low-cost system provides an efficient solution for paper mills while maintaining dependable performance over the long term

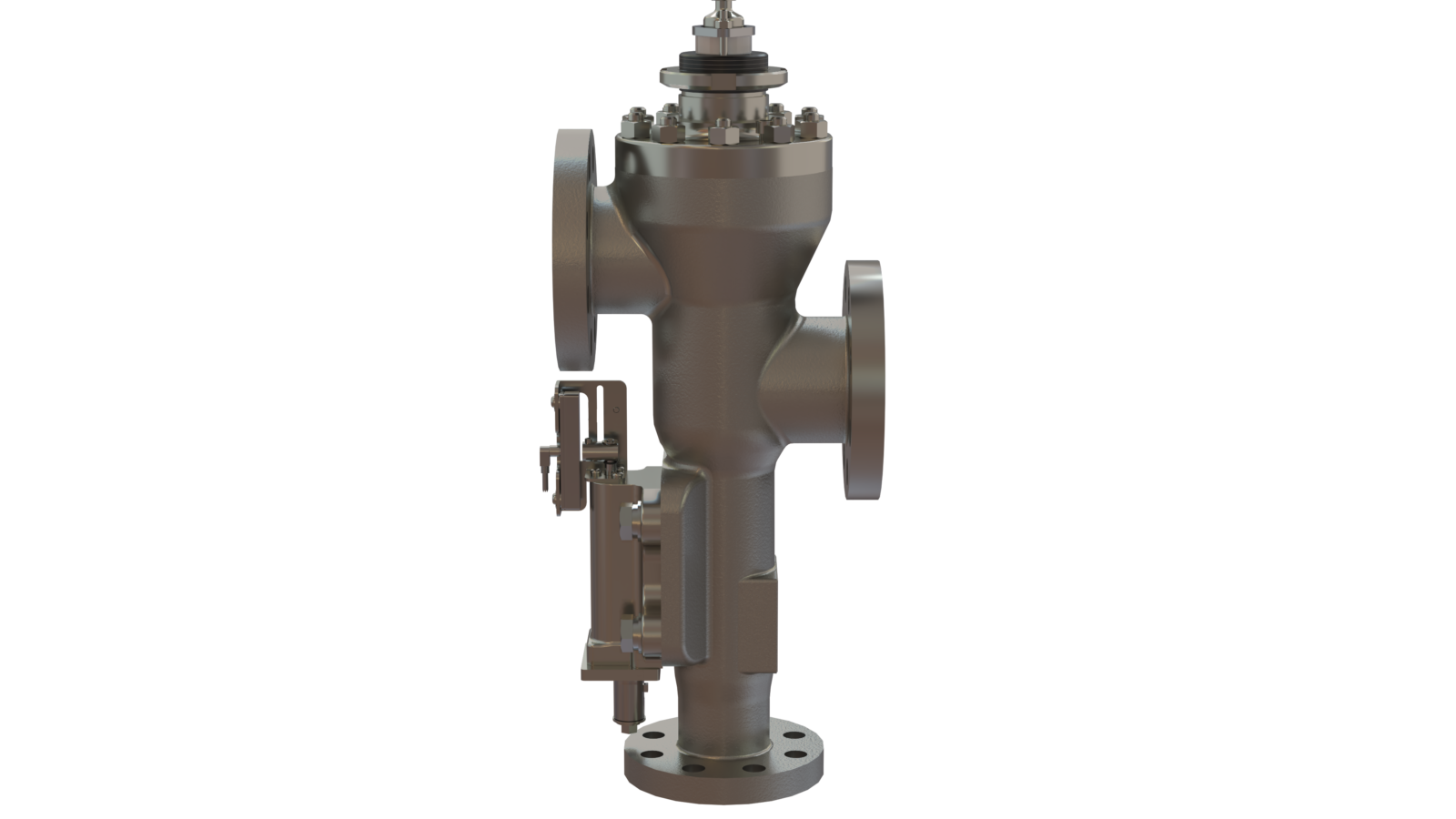

Hydroheater®

Also known as the Jetcooker™, our Hydroheater® has the longest proven history of heating and processing a complex range of liquids and materials. Known for its adjustability, durability, and power, the near century of engineering and innovation behind the design of this workhorse speaks for itself.

- Volume capability: 1 up to 6,700 gpm [0.2 up to 1,522 m³/hr]