Overview

In the pharmaceutical industry, strict sanitation standards and precise temperature control are essential during tank cleaning to prevent contamination and ensure product safety.

Direct Steam Injection (DSI) heaters offer a powerful solution to meet these requirements by providing immediate and consistent heating, which is ideal for Clean-in-Place (CIP) and Sterilize-in-Place (SIP) processes:

- Ensures reliable compliance with GMP and FDA standards through precise temperature control and easy data logging for quality audits.

- Delivers instant, precise heating for effective cleaning, maintaining consistent temperatures that optimize detergents and disinfectants, ensuring thorough sanitation and regulatory compliance

- Increases energy efficiency by injecting steam directly, achieving nearly 100% thermal efficiency and reducing operational costs while supporting sustainability

- Reduces water and chemical usage by rapidly heating cleaning solutions, minimizing reheating needs, and creating a more sustainable cleaning cycle

- Ensures reliable compliance with GMP and FDA standards through precise temperature control and easy data logging for quality audits

- Lowers maintenance needs with fewer moving parts and a direct injection design, reducing downtime and keeping tank cleaning processes on schedule

- Enhances safety by eliminating intermediary surfaces, minimizing contamination risks, and achieving sterilizing temperatures for CIP and SIP applications

- Offers a compact design that integrates easily into existing systems, providing flexibility for retrofits or new installations while optimizing facility layout

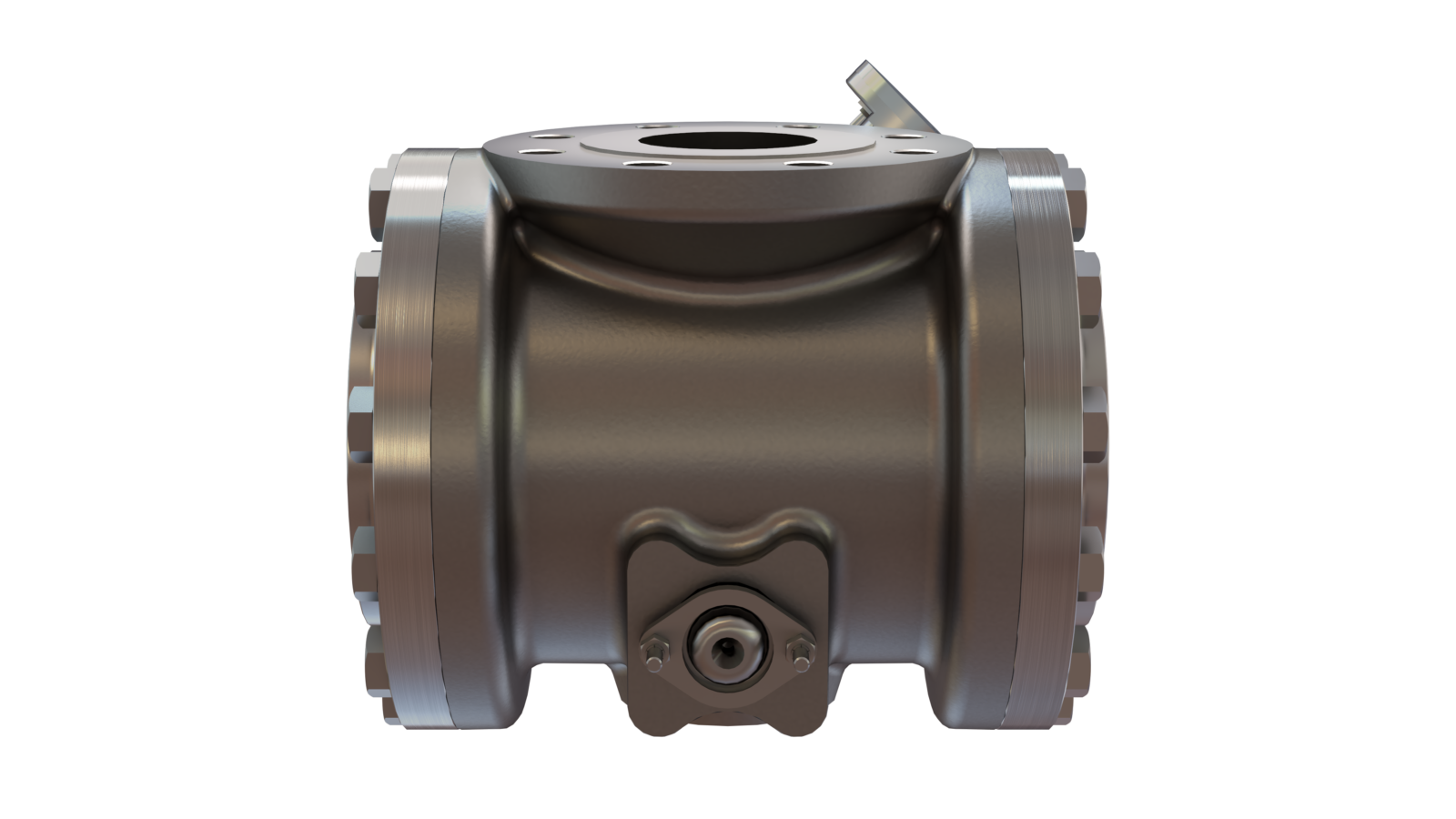

NOH™ (Non-Obstructing Heater)

The Non-Obstructing Heater is rugged enough to handle even the toughest abrasive materials, like sand and grit, to fibrous materials and large particulates.

- Its non-obstructive design protects against plugging, fouling, and pressure drop with its powerful, unrestricted flow.

- Volume capability: 30 up to 3,035 gpm [6.8 up to 689 m³/hr]

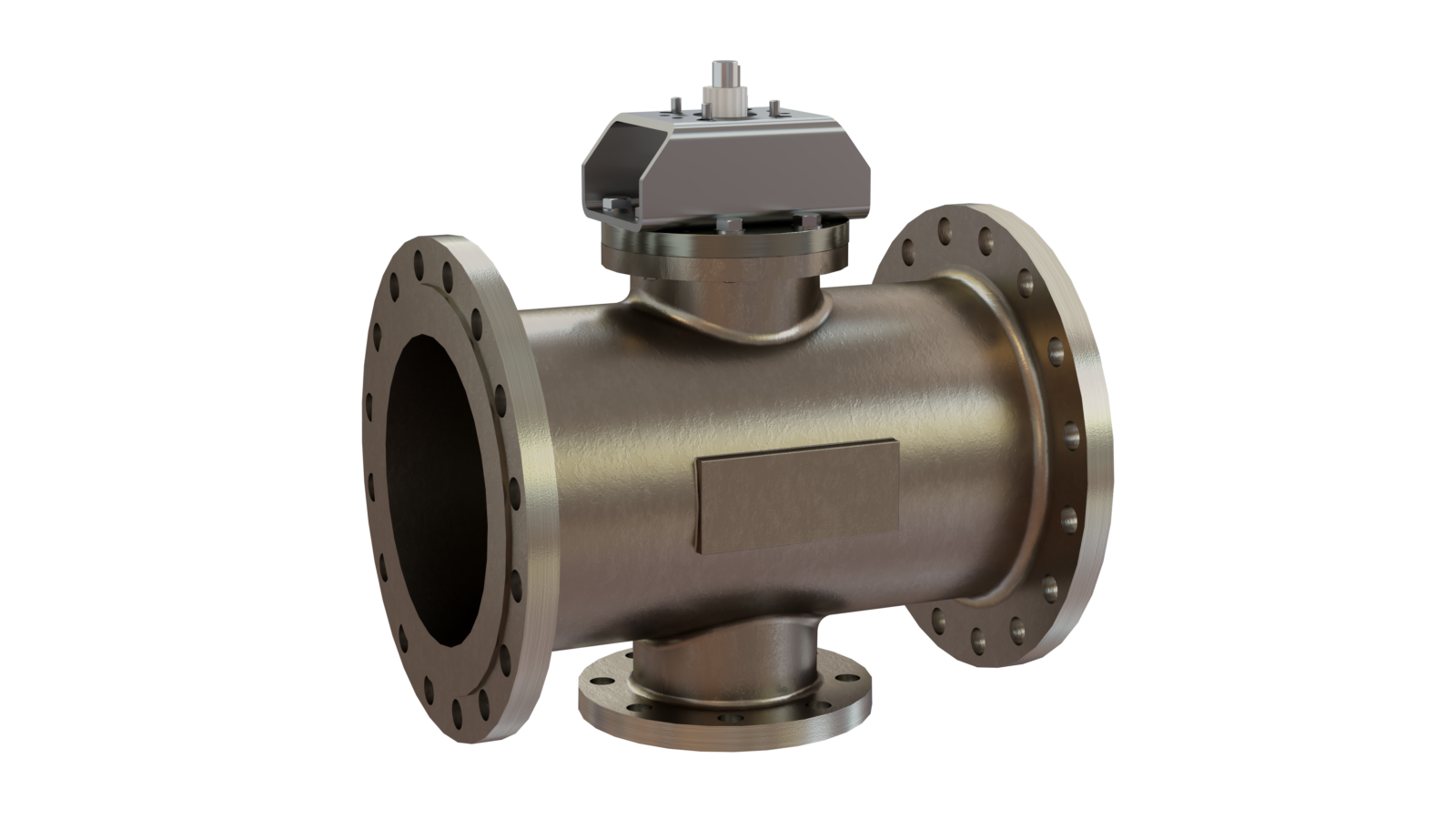

Solaris®

Perfect for viscous slurries, the Solaris® heater features an optimized straight-through design and low shear flow perfect for heavy slurries with medium consistency or higher solid contents. The flow diffuser injects steam across the entire cross-section to ensure thorough mixing and a uniform temperature profile even at a high volume and flow rate.

- Volume capability: 5 up to 25,000 gpm [1 up to 5,678 m³/hr]

Hydron™

The Hydron™ 400 Series is the most precise, accurate, versatile Sanitary Hydroheater. Its modular 3-A-certified design delivers optimal process flexibility and stability in an easy-to-use and maintain design.

- Volume capability: 1 up to 460 gpm [0.2 up to104.5 m³/hr]

EZ Heater®

The EZ Heater® is the industry leader in all hot water applications with its unique internal modulation, and self-cleaning ability. With on-demand hot water where you need it, the EZ Heater is ideal for washing stations, Clean in Place (CIP) systems, and anywhere reliable hot water is needed.

- Volume capability: 2 up to 1,350 gpm [.5 up to 306 m3/hr]