Overview

In chemical production, washing tank cars is crucial to maintaining a contamination-free environment, ensuring they are prepared for safe reuse or proper disposal. This process relies on precise heating of the wash fluid to effectively remove residues, contaminants, and potentially hazardous substances. Safely handling chemicals through proper dilution minimizes the risk of cross-contamination, ensuring a safer and more efficient cleaning process.

Direct Steam Injection (DSI) heaters are ideal for heating wash fluids in tank car cleaning applications, offering speed, energy efficiency, and reliability over traditional heating methods:

- Provides immediate heating for faster, more efficient tank car washing cycles, improving turnaround times and ensuring effective residue removal

- Achieves near 100% thermal efficiency by directly injecting steam into wash fluid, reducing energy waste and lowering operating costs in high-demand environments

- Reduces fouling and maintenance requirements by eliminating intermediary surfaces, extending equipment lifespan, and minimizing downtime for maintenance

- The system ensures precise temperature control for safe and compliant cleaning, allowing temperature adjustments to match specific residue types, as well as the pH and base properties of chemicals, to meet safety standards.

- Adapts easily to various wash cycles and flow rates, maintaining consistent performance for a range of cleaning needs in chemical facilities

- Compact design optimizes facility space, allowing easy integration into existing systems and efficient use of limited floor space

- Lowers water and energy usage, supporting sustainability goals and reducing the environmental impact of tank car washing

- Offers reliable, low-disruption performance with fewer moving parts, supporting continuous operations and minimizing delays in production.

- Available in material options suitable for corrosive and abrasive environments, ensuring durability and reliability.

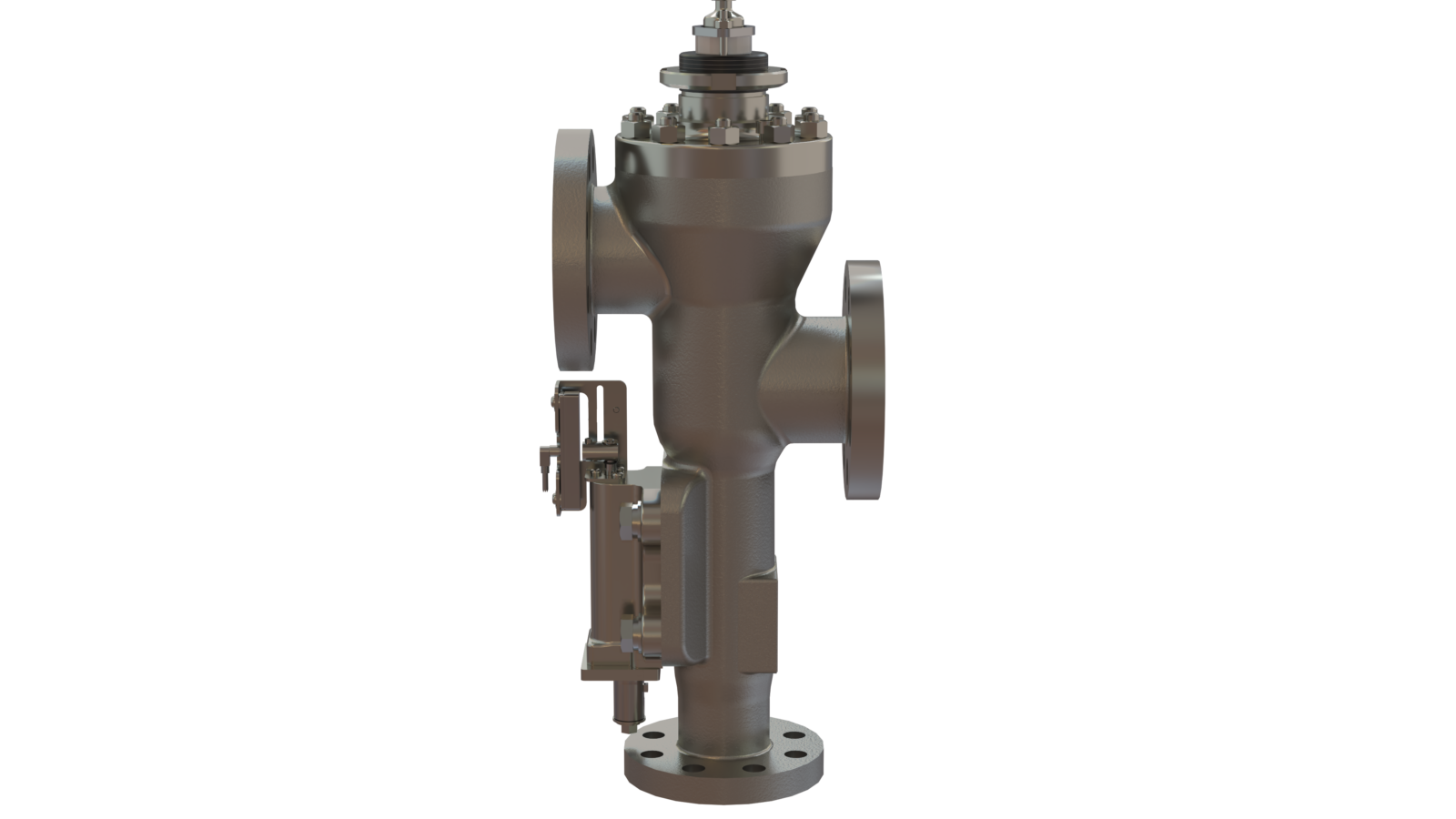

Hydroheater®

Also known as the Jetcooker™, our Hydroheater® has the longest proven history of heating and processing a complex range of liquids and materials. Known for its adjustability, durability, and power, the near century of engineering and innovation behind the design of this workhorse speaks for itself.

- Volume capability: 1 up to 6,700 gpm [0.2 up to 1,522 m³/hr]

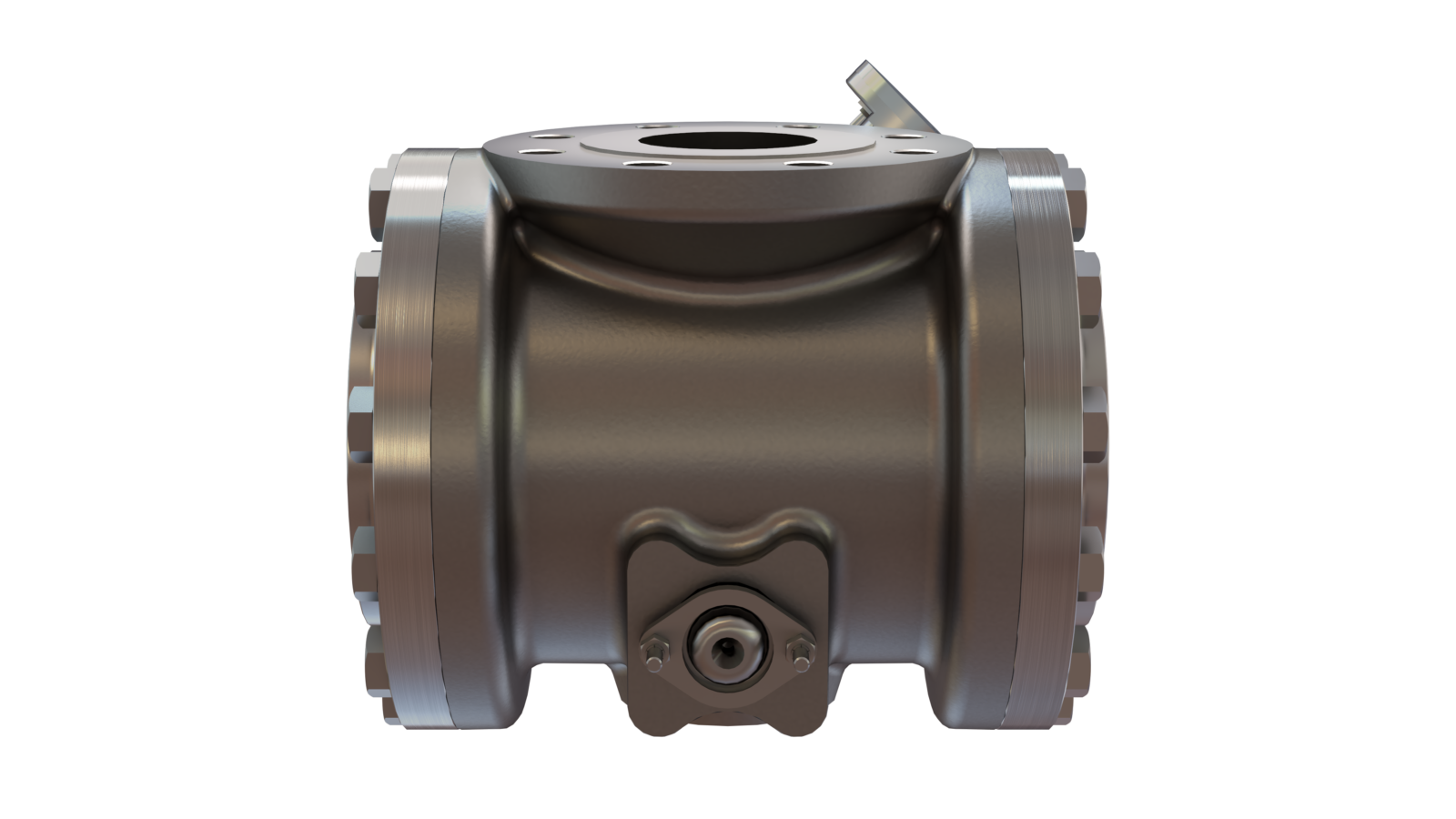

NOH™ (Non-Obstructing Heater)

The Non-Obstructing Heater is rugged enough to handle even the toughest abrasive materials, like sand and grit, to fibrous materials and large particulates.

- Its non-obstructive design protects against plugging, fouling, and pressure drop with its powerful, unrestricted flow.

- Volume capability: 30 up to 3,035 gpm [6.8 up to 689 m³/hr]

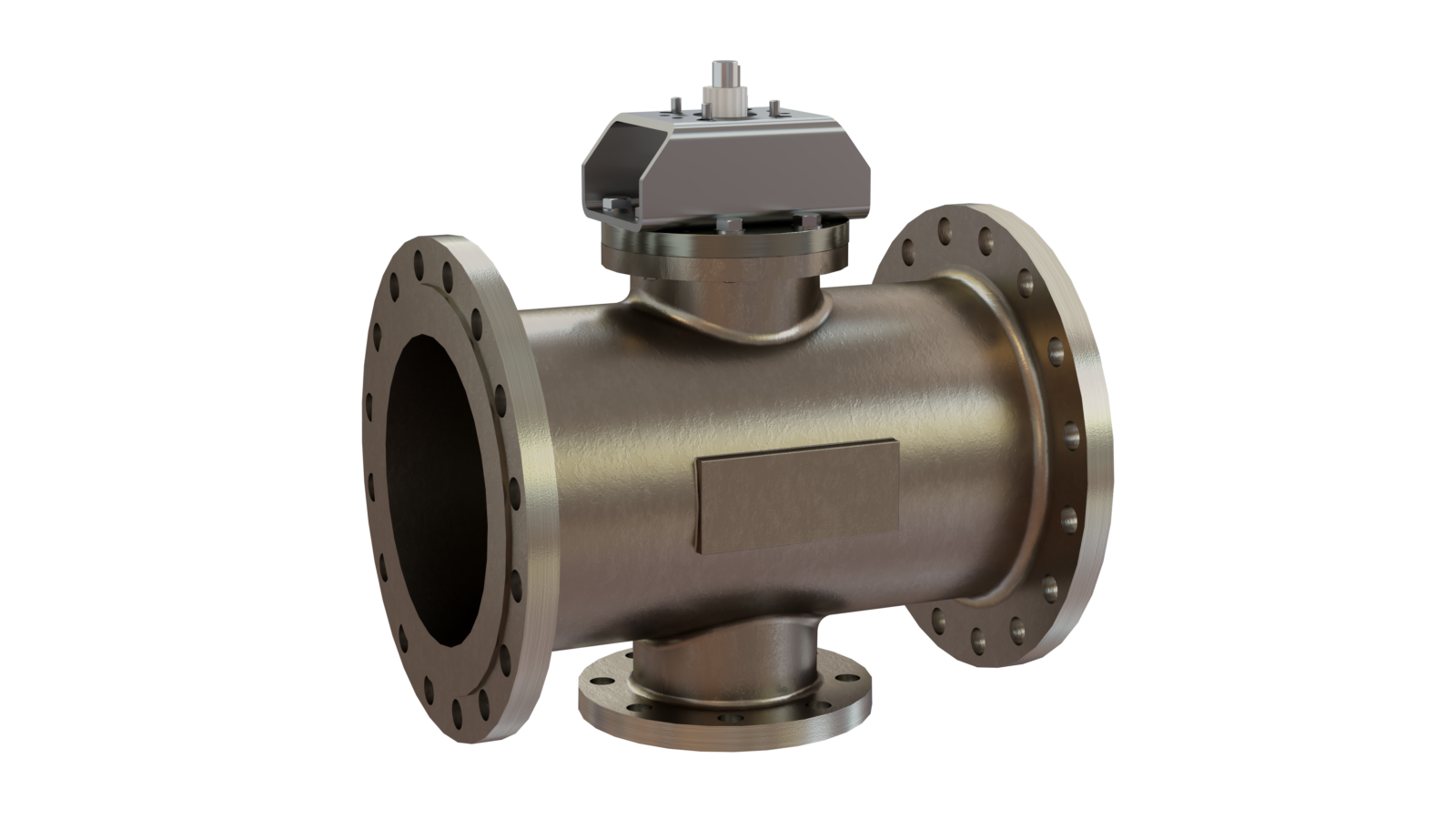

Solaris®

Perfect for viscous slurries, the Solaris® heater features an optimized straight-through design and low shear flow perfect for heavy slurries with medium consistency or higher solid contents. The flow diffuser injects steam across the entire cross-section to ensure thorough mixing and a uniform temperature profile even at a high volume and flow rate.

- Volume capability: 5 up to 25,000 gpm [1 up to 5,678 m³/hr]