Overview

Wastewater containing fats, oils, and grease (FOG) presents unique challenges for treatment facilities due to FOG materials’ viscous, hydrophobic nature. These materials can cause blockages, reduce equipment efficiency, and increase treatment costs. Efficient heating is critical in breaking down FOG-laden wastewater, enhancing separation processes, and supporting optimal treatment performance.

Direct Steam Injection (DSI) heaters provide a highly effective solution for heating FOG wastewater, allowing treatment plants to manage these complex waste streams efficiently:

- Enhances FOG breakdown and flowability, reducing viscosity for easier pumping, separation, and processing while minimizing equipment blockages

- Improves separation efficiency, heating wastewater to an ideal temperature for dissolving fats and oils, which eases downstream filtration and biological treatment

- Reduces fouling and simplifies maintenance by eliminating direct heating surfaces, minimizing buildup from fats and oils, and cutting maintenance costs and downtime

- Provides consistent process control, maintaining optimal temperatures to prevent thermal shock and ensure effective FOG treatment throughout the system

- Increases thermal efficiency, achieving close to 100% energy transfer and reducing operational costs and energy usage for sustainable treatment

- Controls odors in FOG wastewater treatment by rapidly reaching target temperatures and containing emissions within the DSI system

- Boosts processing speed for higher throughput, enabling faster temperature increases and improving capacity to handle high volumes of FOG wastewater

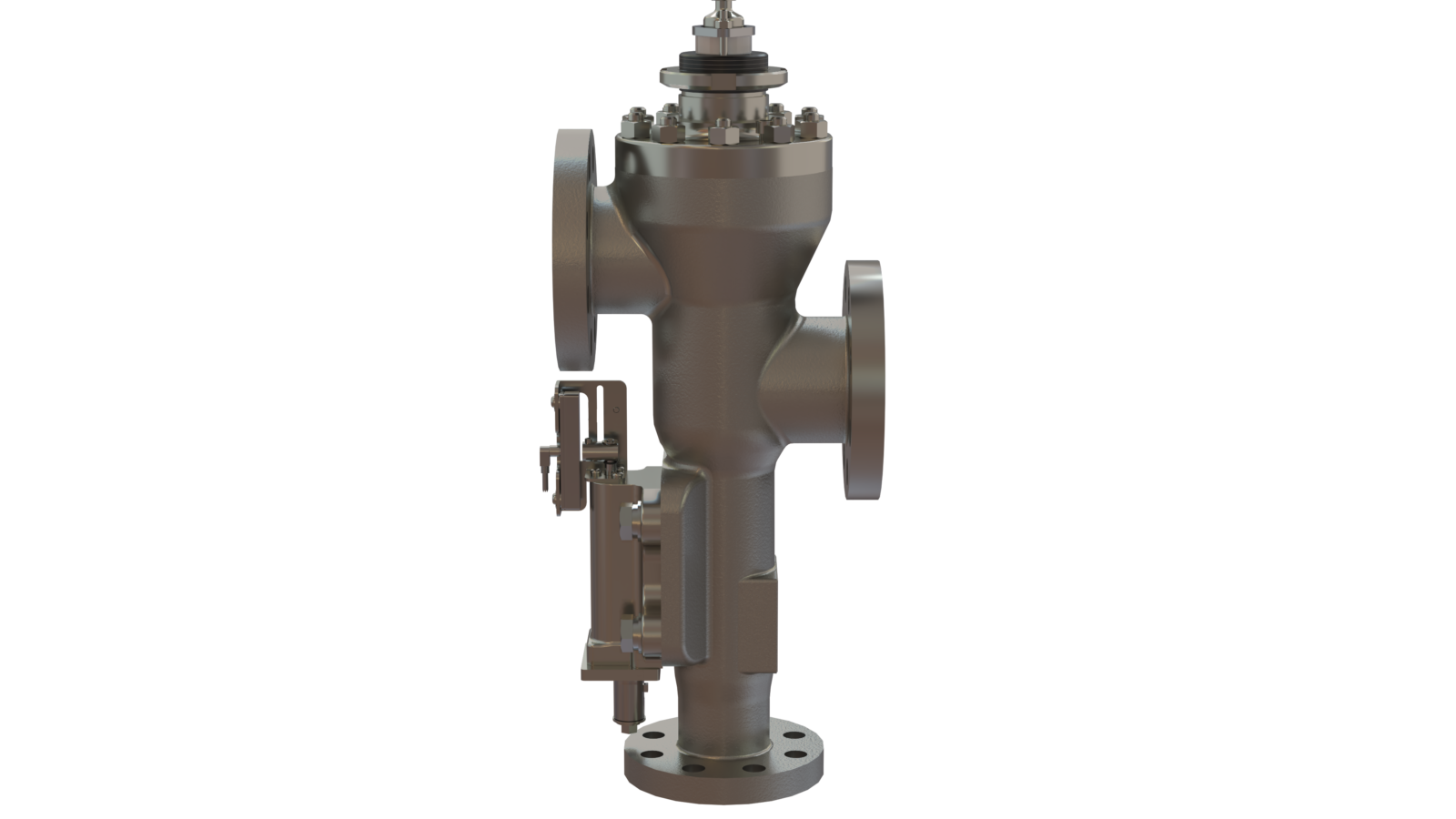

Hydroheater®

Also known as the Jetcooker™, our Hydroheater® has the longest proven history of heating and processing a complex range of liquids and materials. Known for its adjustability, durability, and power, the near century of engineering and innovation behind the design of this workhorse speaks for itself.

- Volume capability: 1 up to 6,700 gpm [0.2 up to 1,522 m³/hr]

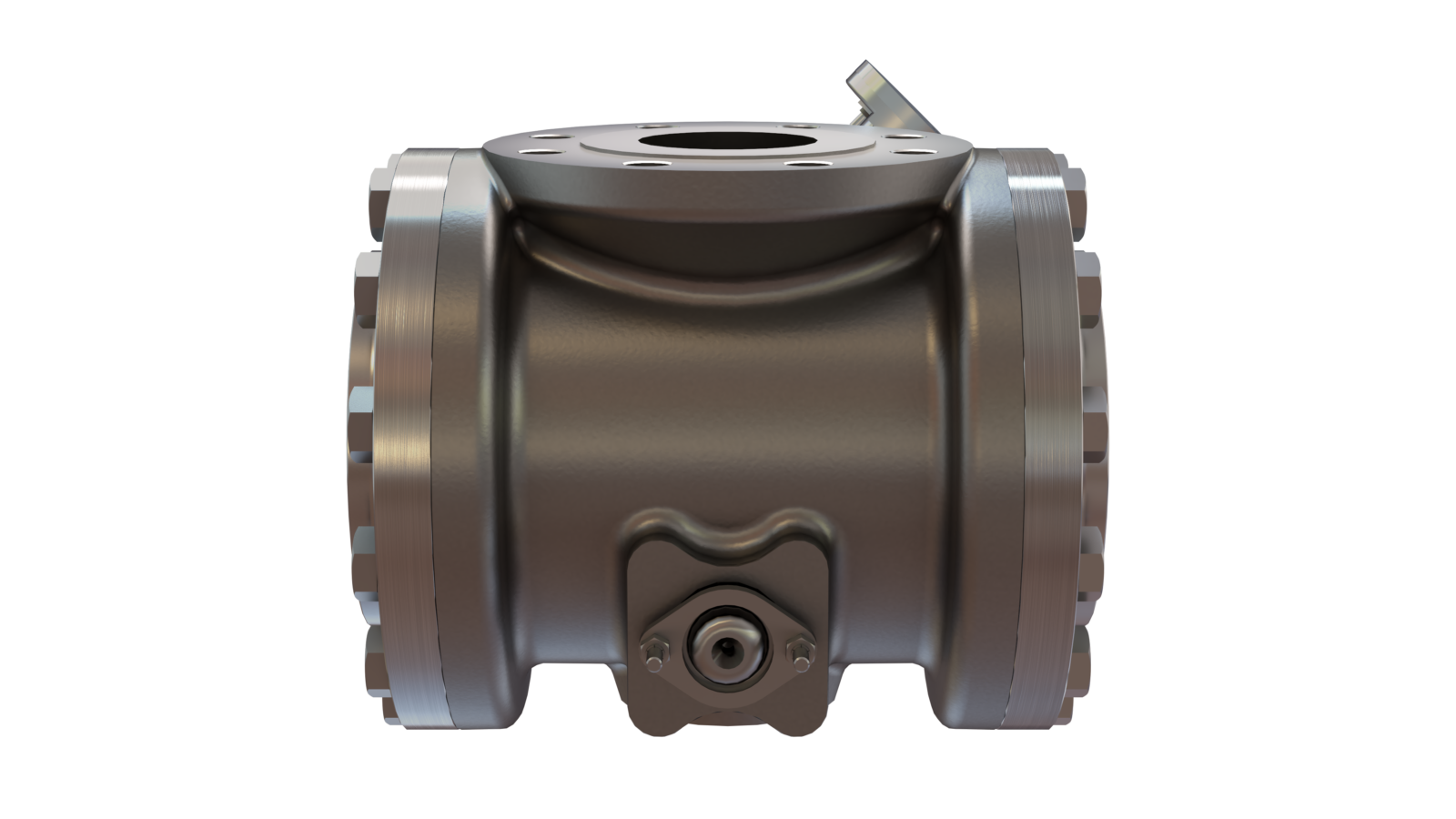

NOH™ (Non-Obstructing Heater)

The Non-Obstructing Heater is rugged enough to handle even the toughest abrasive materials, like sand and grit, to fibrous materials and large particulates.

- Its non-obstructive design protects against plugging, fouling, and pressure drop with its powerful, unrestricted flow.

- Volume capability: 30 up to 3,035 gpm [6.8 up to 689 m³/hr]

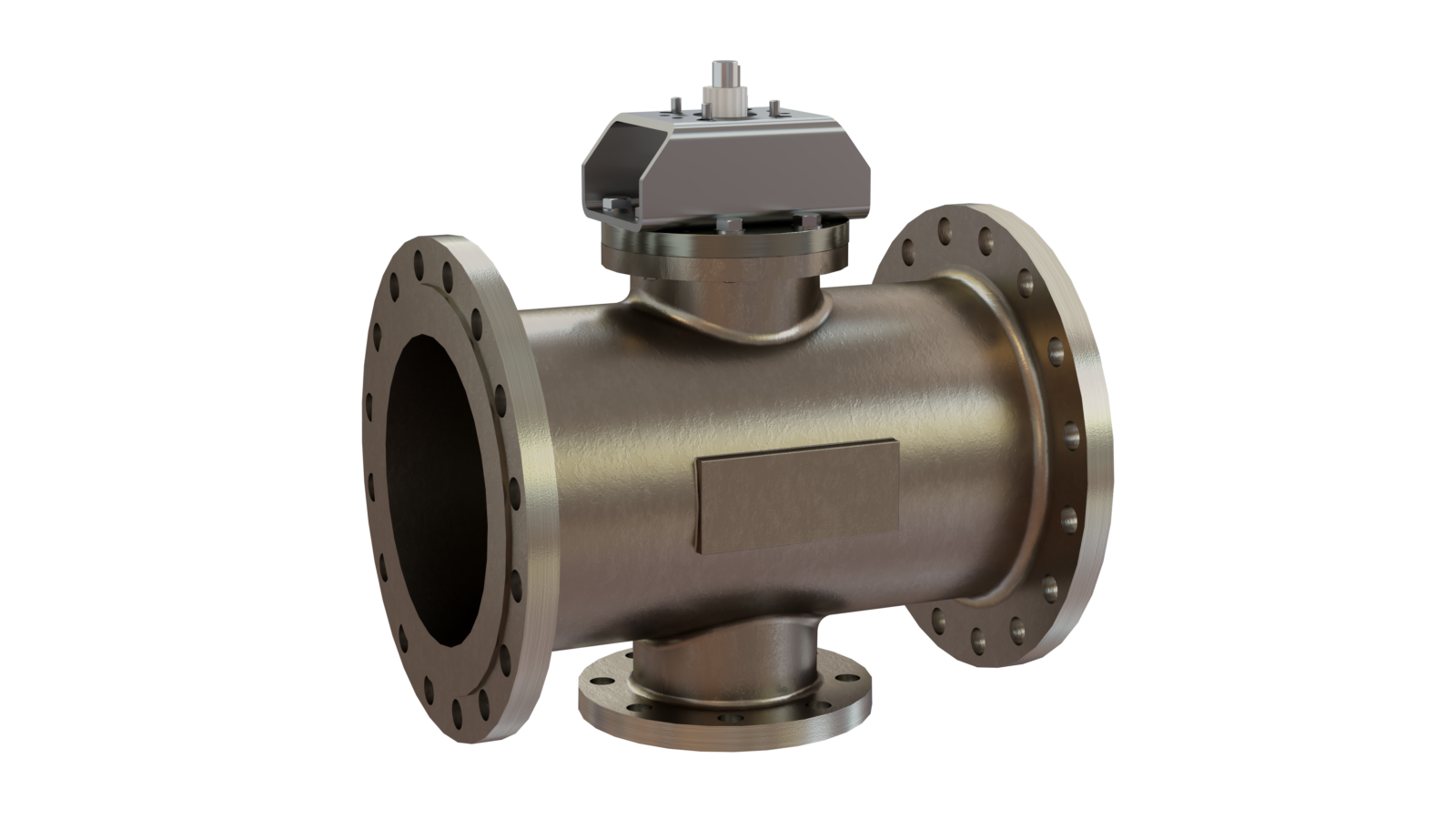

Solaris®

Perfect for viscous slurries, the Solaris® heater features an optimized straight-through design and low shear flow perfect for heavy slurries with medium consistency or higher solid contents. The flow diffuser injects steam across the entire cross-section to ensure thorough mixing and a uniform temperature profile even at a high volume and flow rate.

- Volume capability: 5 up to 25,000 gpm [1 up to 5,678 m³/hr]