Overview

In food processing, producing protein-based products—such as plant-based proteins, protein isolates, and concentrates—requires precision heating to maintain product quality, improve functionality, and meet food safety standards. By directly injecting steam, DSI heaters allow food processors to achieve on-demand, uniform heating, ensuring that each batch meets the highest quality, texture, and safety standards.

Direct Steam Injection (DSI) heaters offer a highly efficient, controllable heating solution that aligns perfectly with protein production demands and provides numerous benefits:

- Maintains protein functionality and nutrition with precise, on-demand heating that minimizes degradation and preserves the protein’s intended qualities

- Delivers consistent texture and solubility, preventing clumping and separation, ideal for smooth protein shakes and meat alternatives

- Ensures product safety by achieving fast, even pasteurization that eliminates cold spots and meets safety standards

- Increases throughput with instant heating, allowing faster processing for high-demand protein production

- Reduces fouling and simplifies cleaning by eliminating intermediary surfaces that can accumulate protein deposits

- Lowers operating costs with high thermal efficiency, directly transferring energy to the product and reducing energy waste

- Provides batch-to-batch consistency through precise temperature control, supporting uniform product quality across production runs

- Enhances emulsification for stable protein blends, ensuring homogeneity in plant-based milks, protein shakes, and meat alternatives

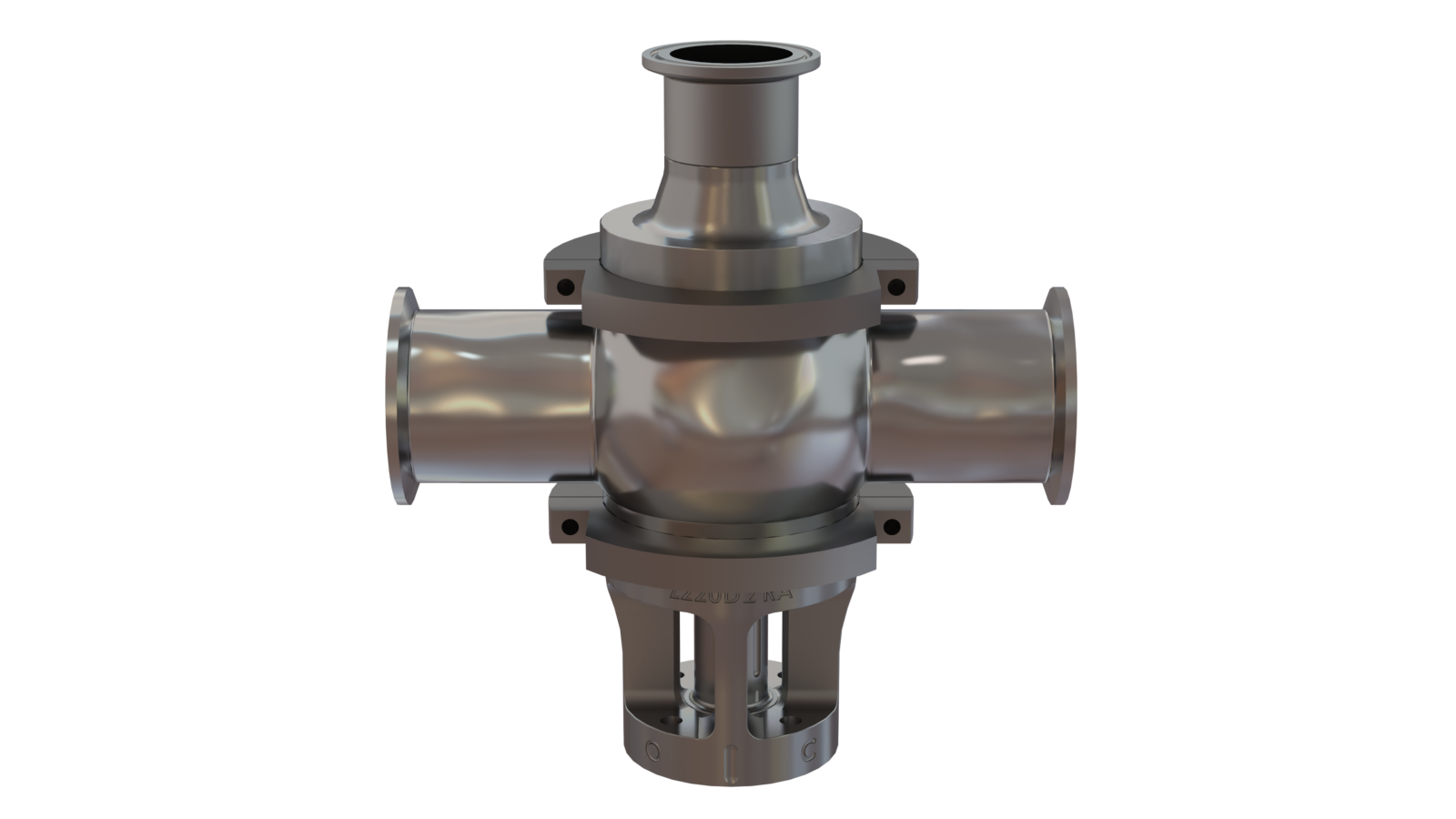

Hydron™

The Hydron™ 400 Series is the most precise, accurate, versatile Sanitary Hydroheater. Its modular 3-A-certified design delivers optimal process flexibility and stability in an easy-to-use and maintain design.

- Volume capability: 1 up to 460 gpm [0.2 up to104.5 m³/hr]

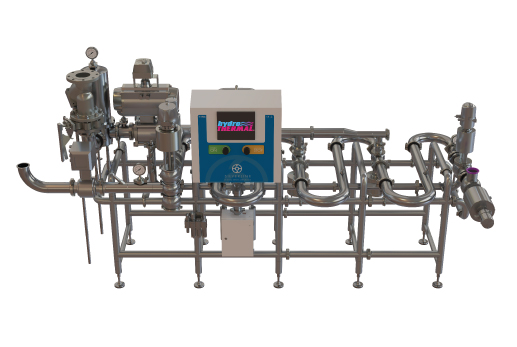

Infuze

Compact and fully sanitary cooking skid that helps products achieve finished recipe results, pasteurization, or blended emulsification through 3-A, EHEDG, and FDA certifications.

- Volume capability: 3 up to 255 gpm [0.7 up to 57.9 m3/hr]

Silverline™

The Silverline™ is a polished stainless-steel steel system engineered to replicate specified processing profiles precisely. Despite its simple appearance, it incorporates thousands of hours of engineering into a single, advanced machine – acclaimed as one of the most advanced food and beverage processing systems globally.

- Volume capability: 5 up to 200 gpm [1.1 up to 45 m3/hr

EZ Heater®

The EZ Heater® is the industry leader in all hot water applications with its unique internal modulation and self-cleaning ability. With on-demand hot water where you need it, the EZ Heater is ideal for washing stations, Clean in Place (CIP) systems, and anywhere reliable hot water is needed.

- Volume capability: 2 up to 1,350 gpm [.5 up to 306 m3/hr]