Overview

From mashing and wort preparation to cleaning and pasteurization, beer production relies on precise heating across various stages. Hydro-Thermal’s Direct Steam Injection heaters help improve efficiency, optimize flavor consistency, and meet sanitation requirements, making them an ideal solution for brewers of all sizes.

Direct Steam Injection (DSI) heaters bring unique benefits to breweries by delivering on-demand, efficient, and accurate heat directly into process fluids:

- Provides on-demand, precise heating by directly injecting steam, reaching target temperatures almost instantly to preserve enzyme activity and ensure consistent starch-to-sugar conversion for optimal mash quality and flavor

- Maximizes energy efficiency with near 100% thermal transfer, cutting fuel use and energy costs, supporting sustainable and cost-effective brewing

- Enhances product quality with steady heating, maintaining consistent enzyme activity and flavor, producing uniform taste across batches to strengthen brand reliability

- Delivers even heating during wort boiling, aiding in protein coagulation and compound removal for a clearer wort and stable final product with reduced boiling times

- Shortens cleaning cycles by quickly heating water for CIP systems, ensuring thorough sanitation, reducing downtime, and keeping production on schedule

- Saves space with a compact design that integrates easily into brewery layouts, ideal for optimizing floor space in smaller or craft breweries

- Ensures controlled pasteurization in non-filtered beers, maintaining precise temperatures to preserve freshness, carbonation, and flavor while extending shelf life

- Reduces maintenance with direct steam injection, eliminating fouling, extending equipment life, and minimizing downtime for consistent operations

- Supports sustainability by lowering water and fuel use, reducing overall consumption, cutting emissions, and meeting eco-friendly standards

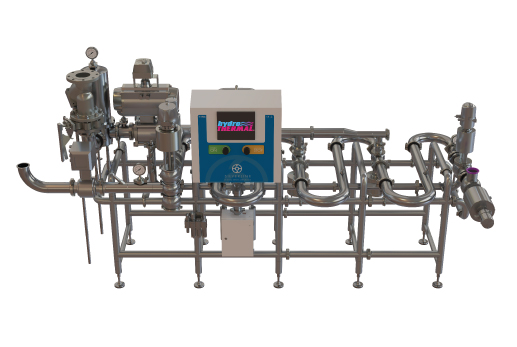

Infuze

Compact and fully sanitary cooking skid that helps products achieve finished recipe results, pasteurization or blended emulsification through 3-A, EHEDG and FDA certifications.

- Volume capability: 3 up to 255 gpm [0.7 up to 57.9 m3/hr]

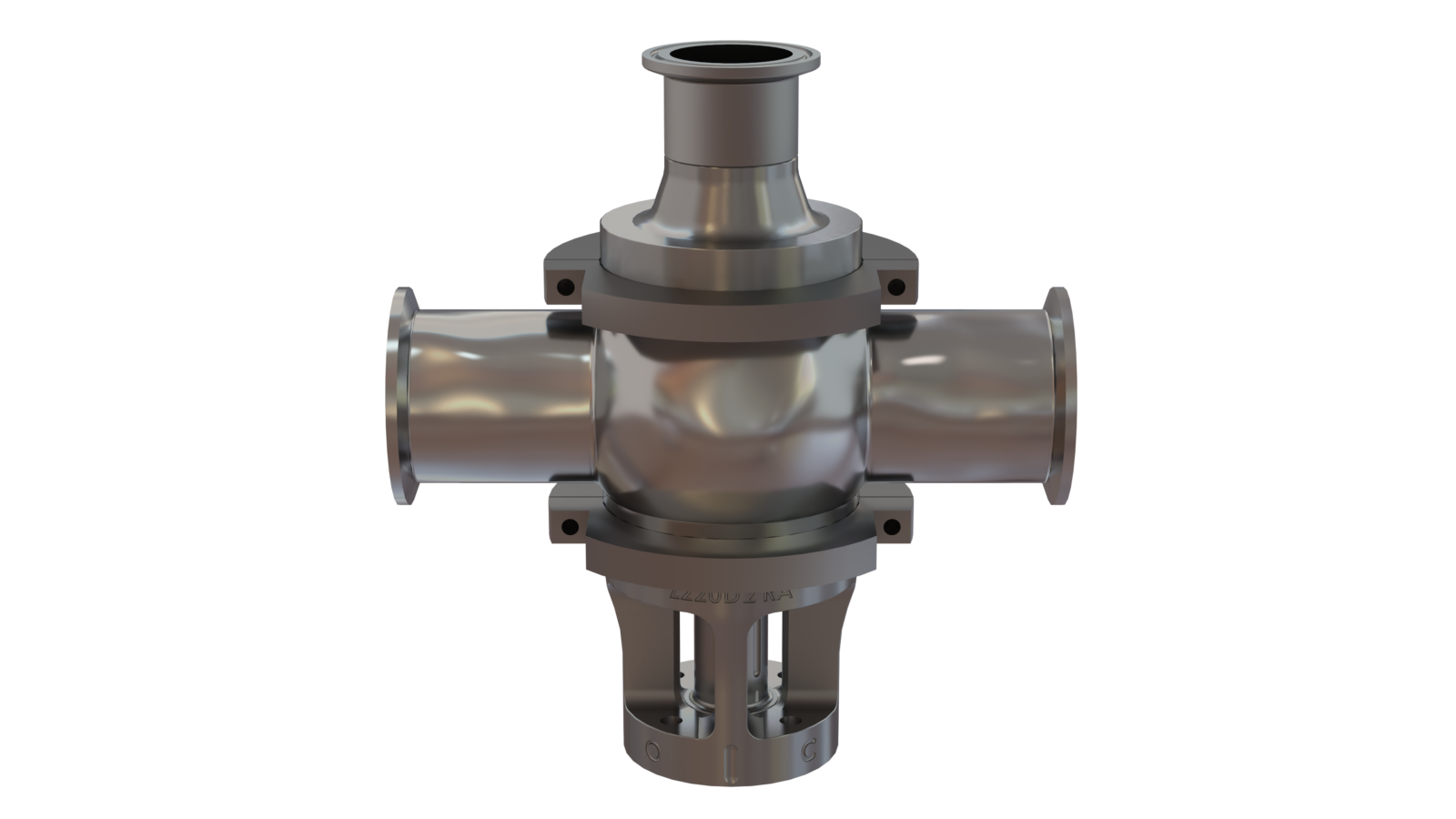

Hydron™

The Hydron™ 400 Series is the most precise, accurate, versatile Sanitary Hydroheater. Its modular 3-A-certified design delivers optimal process flexibility and stability in an easy-to-use and maintain design.

- Volume capability: 1 up to 460 gpm [0.2 up to 104.5 m³/hr]

Silverline™

The Silverline™ is a polished stainless-steel steel system engineered to replicate specified processing profiles precisely. It is 3-A certified and meets EHEDG, CE, and FDA requirements. Despite its simple appearance, it incorporates thousands of hours of engineering into a single, advanced machine – acclaimed as one of the most advanced food and beverage processing systems globally.

- Volume capability: 5 up to 200 gpm [1.1 up to 45 m3/hr]

EZ Heater®

The EZ Heater® is the industry leader in all hot water applications with its unique internal modulation and self-cleaning ability. With on-demand hot water where you need it, the EZ Heater is ideal for washing stations, Clean in Place (CIP) systems, and anywhere reliable hot water is needed.

- Volume capability: 2 up to 1,350 gpm [.5 up to 306 m3/hr]