Overview

Ethanol producers often face significant challenges in maintaining consistent mash temperatures, particularly in the beer column, where temperature control is critical to the distillation process. Seasonal fluctuations, especially during harsh winter months, can make this task even more difficult, leading to inefficiencies, increased steam consumption, and costly downtime.

Hydro-Thermal’s non-shear heaters are strategically placed after the beer well and beer mash exchangers but before the beer column to maximize the heating benefits.

Ensure that you always reach – and maintain – ideal mash temperature in beer columns, regardless of how cold it is outside with our patented Direct Steam Injection technology that delivers:

- Improved efficiency in distillation to help optimize your processes

- Reduced steam usage through evaporation and the sieve vaporizer

- Extended plant runs on the beer mash exchangers before needing to CIP, resulting in a reduction in chemical usage

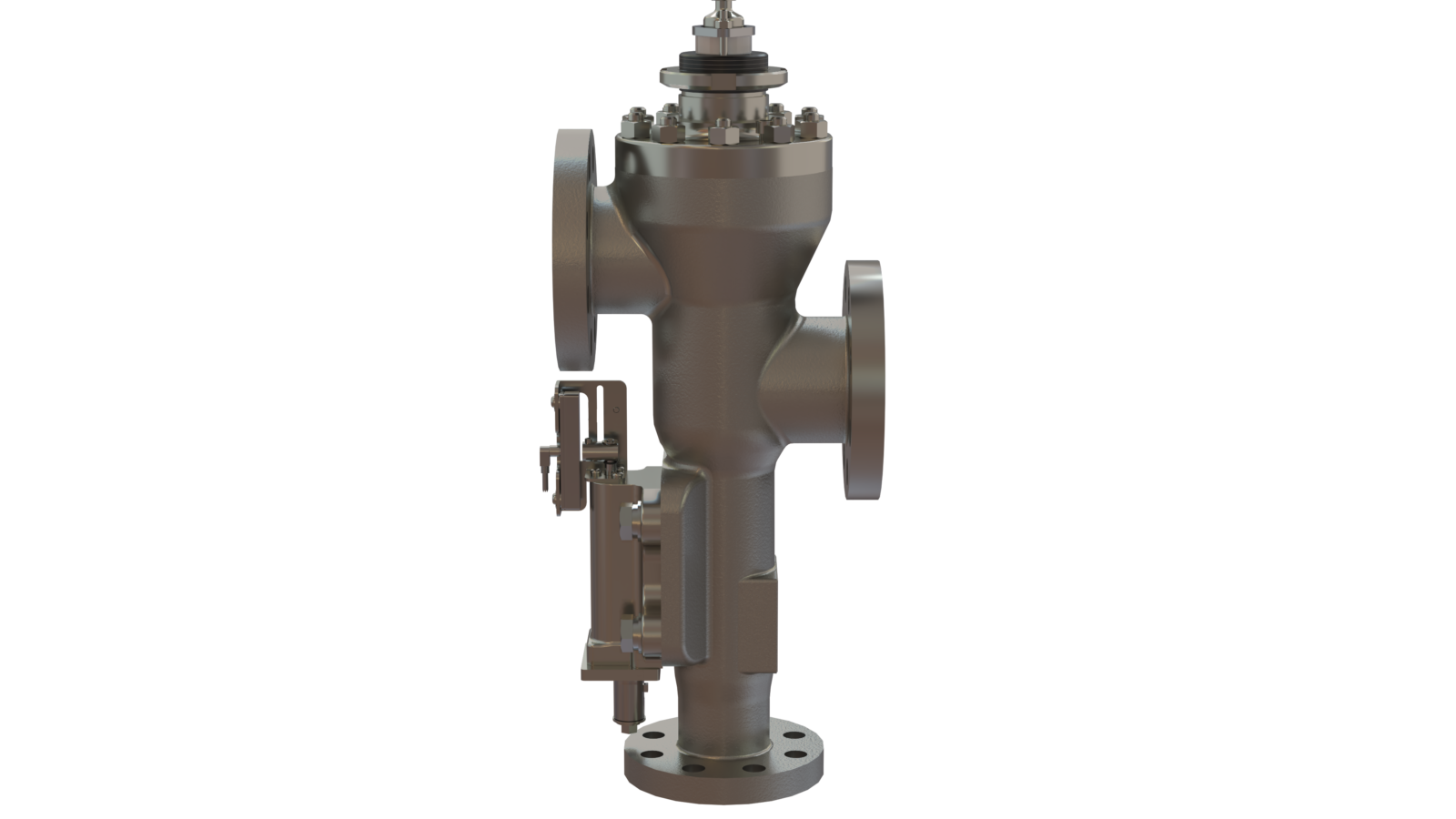

Hydroheater®

Also known as the Jetcooker™, our Hydroheater® has the longest proven history of heating and processing a complex range of liquids and materials. Known for its adjustability, durability, and power, the near century of engineering and innovation behind the design of this workhorse speaks for itself.

- Volume capability: 1 up to 6,700 gpm [0.2 up to 1,522 m³/hr]

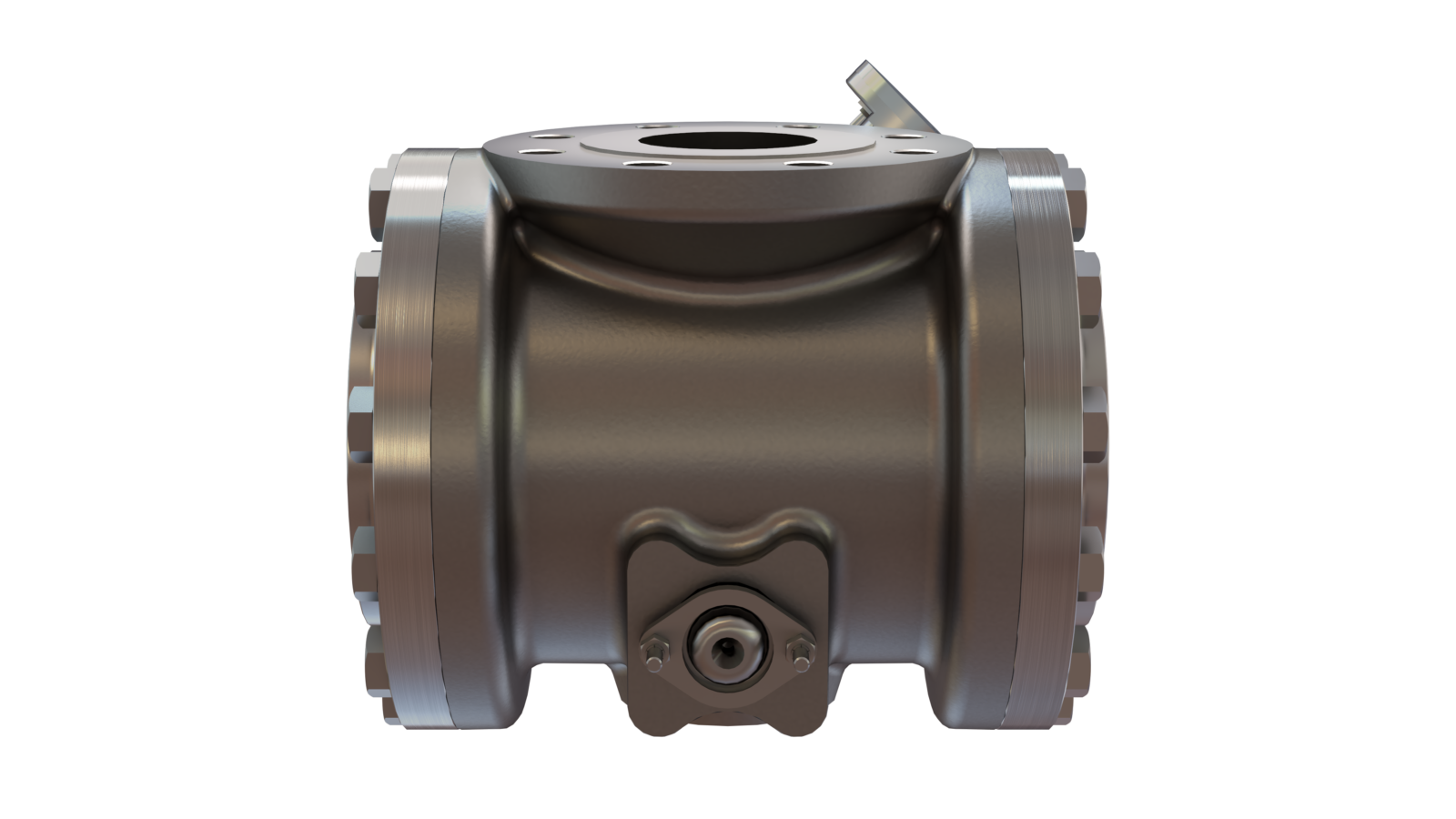

NOH™ (Non-Obstructing Heater)

The Non-Obstructing Heater is rugged enough to handle even the toughest abrasive materials, like sand and grit, to fibrous materials and large particulates.

- Its non-obstructive design protects against plugging, fouling, and pressure drop with its powerful, unrestricted flow.

- Volume capability: 30 up to 3,035 gpm [6.8 up to 689 m³/hr]

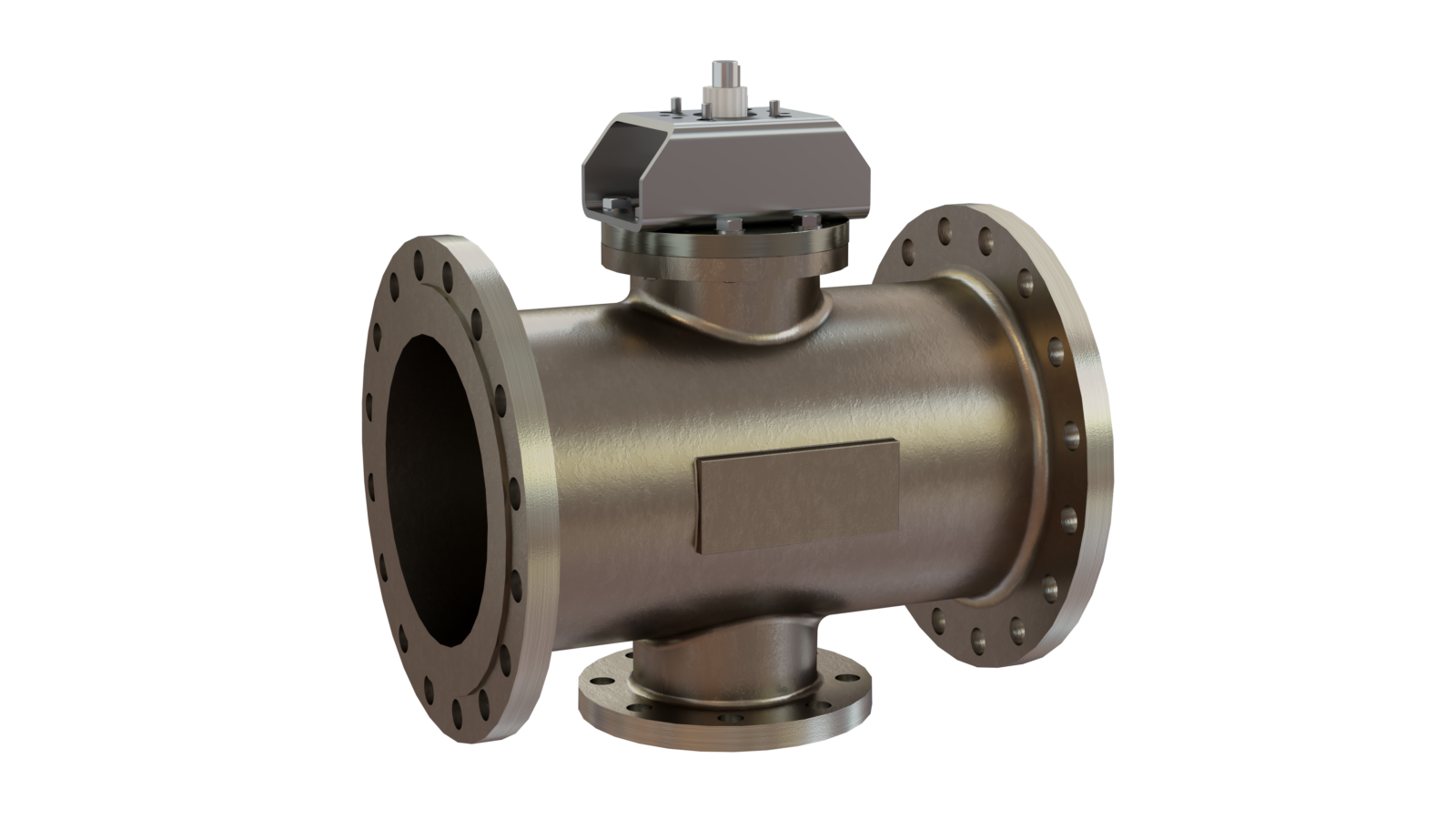

Solaris®

Perfect for viscous slurries, the Solaris® heater features an optimized straight-through design and low shear flow perfect for heavy slurries with medium consistency or higher solid contents. The flow diffuser injects steam across the entire cross-section to ensure thorough mixing and a uniform temperature profile even at a high volume and flow rate.

- Volume capability: 5 up to 25,000 gpm [1 up to 5,678 m³/hr]

EZ Heater®

The EZ Heater® is the industry leader in all hot water applications with its unique internal modulation, and self-cleaning ability. With on-demand hot water where you need it, the EZ Heater is ideal for washing stations, Clean in Place (CIP) systems, and anywhere reliable hot water is needed.

- Volume capability: 2 up to 1,350 gpm [.5 up to 306 m3/hr]