Overview

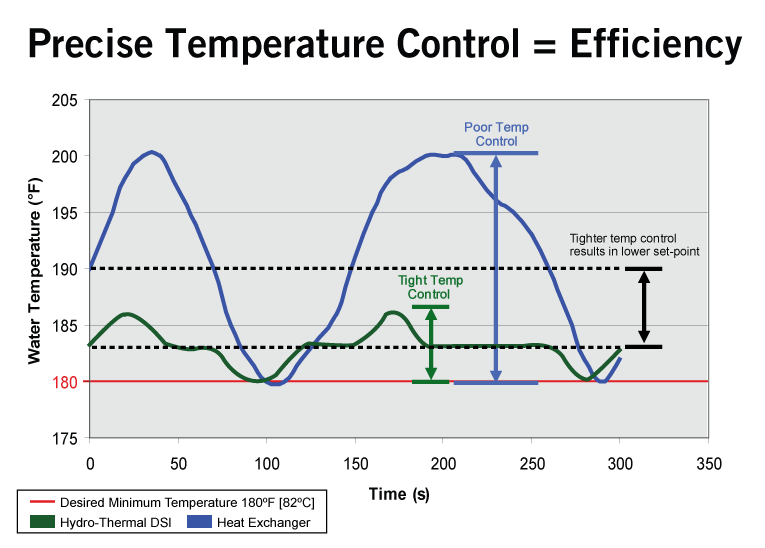

Documented energy savings of up to 30% have been reported when replacing a shell-in-tube or plate and frame heat exchanger with a direct steam injection heater from Hydro-Thermal. Don’t believe us? Use our Energy Saving Calculator to see how much you can save in operating costs by replacing your heat exchanger. Along with providing precise temperatures, these Hydroheaters will help reduce your day-to-day operating costs & improve ROI.

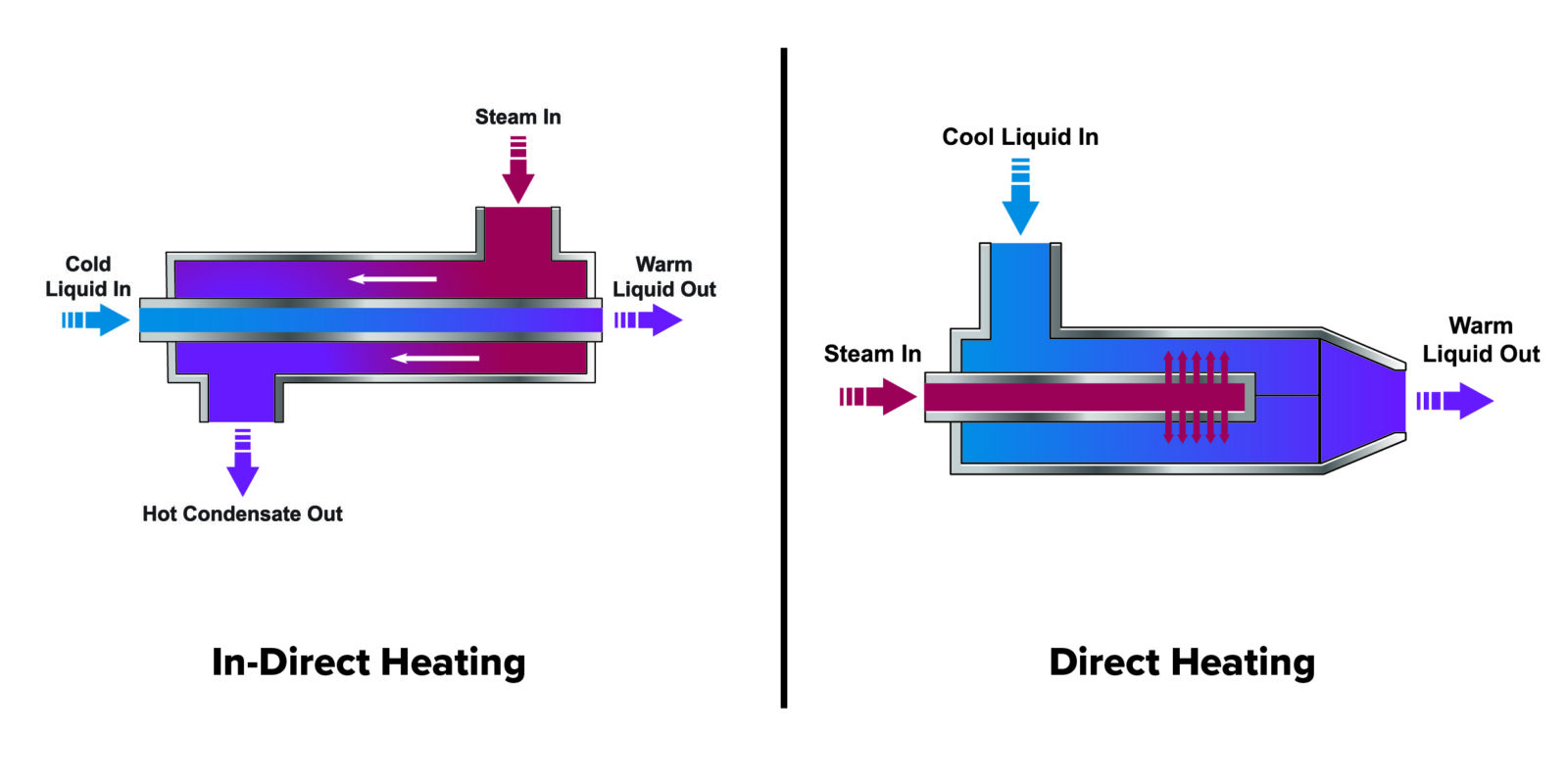

Heat exchangers heat through a metal barrier which does not allow complete energy transfer. On average, 20% of the energy (sensible) is lost to condensate and has to return to the boiler. Direct steam injection heaters are more energy efficient by using 100% of the steam’s energy to heat process fluids or utility water. Hydro-Thermal direct steam heaters are not conventional steam eductors, but a patented 3-way valve with major advantages over all other fluid heating methods, providing 100% thermal efficiency.

Steam Injection Heater Benefits

More reasons to replace heat exchangers or spargers with a steam injection heater, also called Hydroheaters and Jetcookers, from Hydro-Thermal:

- Less maintenance and more up time

- Exacting control of required process conditions and temperature

- Smaller footprint

- Hydro-Thermal expertise, training, support services, and warranty

Eliminate Hot Spots on a Heat Exchanger

Does your heat exchanger unevenly heat? Because heat exchangers use indirect heat transfer through surfaces, they become coated with product or hard water scaling causing the heat exchanger to lose efficiency.

- Hot spots and cool spots may also occur resulting in uneven heating and poor product quality

- Due to our patented self-cleaning design, replacing a heat exchanger with direct steam injection steam cookers solves these problems

- A baby formula maker increased product quality and the bottom line when they switched from a heat exchanger to our Jetcooker™

A Solution for Steam Heaters Foul & Scale

Does your current 3-way valve steam heater scale and foul? Some steam heaters foul and scale because of their inner workings and spring parts causing them to clog and need frequent acid baths. This reduces productivity and increases maintenance costs.

- Hydro-Thermal Hydroheater: Unique stem plug and diffuser enable precise steam injection at sonic velocity via choked flow, resulting in self-cleaning action

- Reliable Process Heater: Energy efficient design minimizes scaling and fouling, ensuring maximum reliability

About Hydro-Thermal

Are you curious about our patented direct steam injection technology? Are you wondering what applications are ideal for direct steam injection? Learn more by clicking on one of the pages below.

Our ProductsFind the Right Hydro-Thermal Product for You

Learn more about our products and where they work best.