How Does Direct Steam Injection Work?

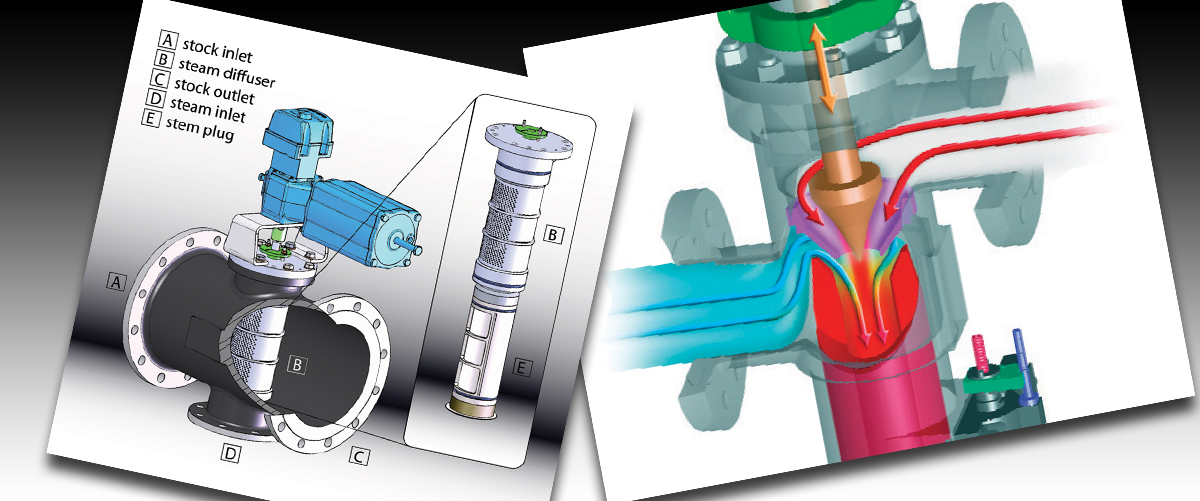

Direct Steam Injection works by directly injecting steam into a process fluid to obtain more rapid heat transfer, resulting in more efficient energy usage than indirect heat exchangers. This efficient process of heating is caused by our direct steam injection Hydroheaters’ ability to control both steam flow and mixing turbulence by using a modulating stem plug and nozzle or diffuser assembly in the heater. This precise mixing of a measured amount of high-velocity steam directly with your liquid or slurry provides an instantaneous heat transfer from steam to the fluid. This heat transfer method allows for 100% thermal efficiency and energy savings of 20-25%.

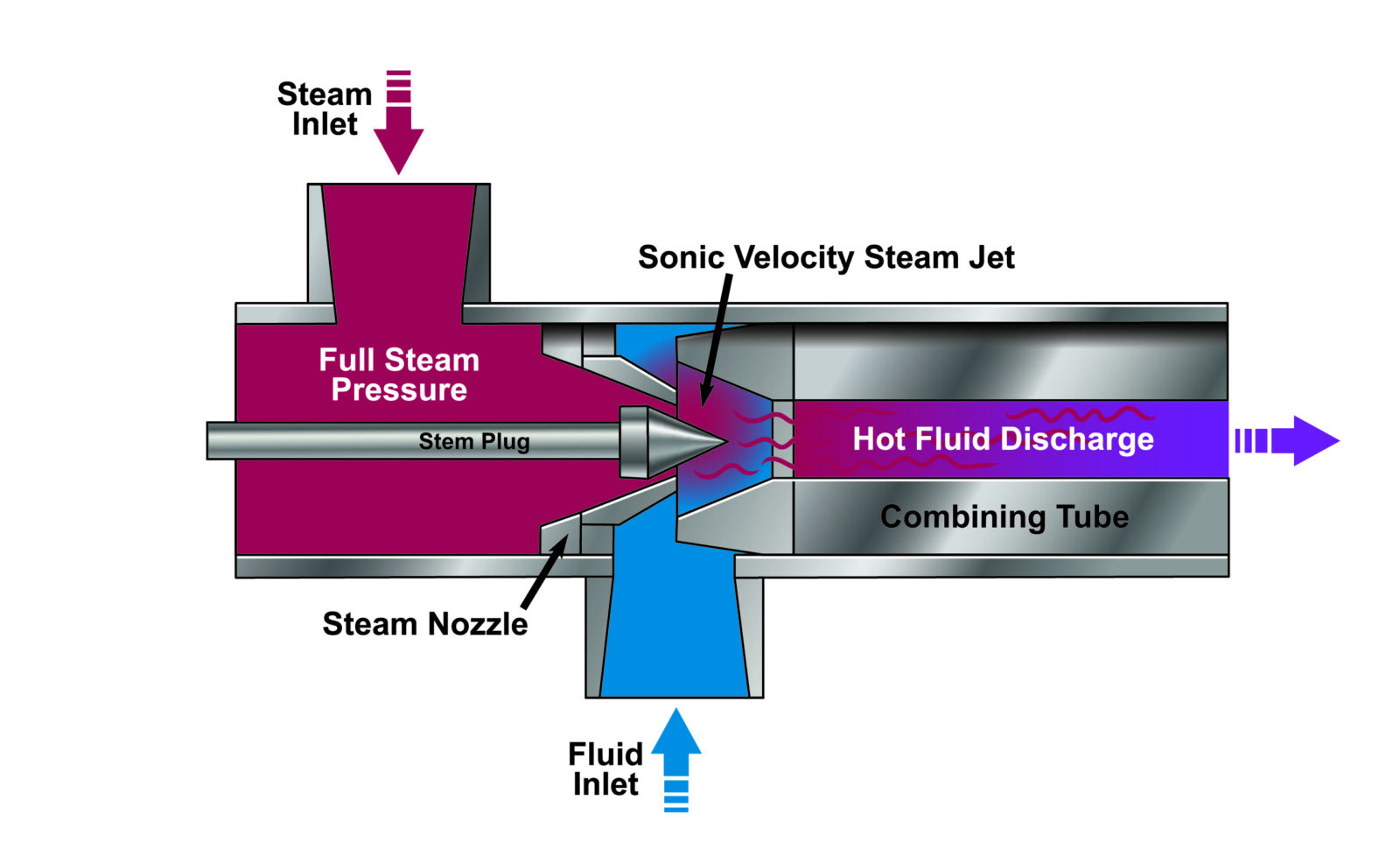

A precisely engineered, variable-area steam nozzle or diffuser meters the flow at the point of injection and contact with the fluid. The large pressure drop from full steam pressure to the process fluid pressure ensures high-velocity choked steam flow and instantaneous mixing of the two streams. When steam flow is choked, its velocity at the nozzle or diffuser exit is constant regardless of the total mass flow injected. The internally modulated Hydro-Thermal heaters control the amount of injection area (cross-sectional area of the nozzle or diffuser opening) to regulate the heat load precisely—the constant steam velocity results in consistent and stable operation across the full range of operations.

Hydro-Thermal’s patented direct steam injection heaters use direct heat exchange to transfer 100% of the steam’s energy for heating liquids and slurries over a wide range of viscosities and solid contents to precise temperatures. A Hydroheater’s internal modulation assures exacting steam control and rapid temperature management and produces predictable results. Each Hydro-Thermal heater has an internal trim custom-designed for each customer’s specific needs and requirements.

Don’t believe us? Head over to our Energy Savings Calculator to get an accurate estimate of how much you can be saving in operating costs.

What is Direct Steam Injection?

As the backbone of our products at Hydro-Thermal, direct steam injection (DSI) technology is at the core of what makes our products so successful. Mixing steam directly with process fluids or slurries is ideal for heating liquids over a wide range of viscosities and solid contents to precise temperatures, while also transferring 100% of steam’s latent and sensible energy.

DSI reaches across all major industries, including Food & Beverage, Ethanol Starch & Sweeteners, and Industrial.

Visit YouTubeExternal vs. Internal Modulation

Externally or Internally modulated direct steam injection refers to how the mass flow of steam injected into the process fluid is controlled.

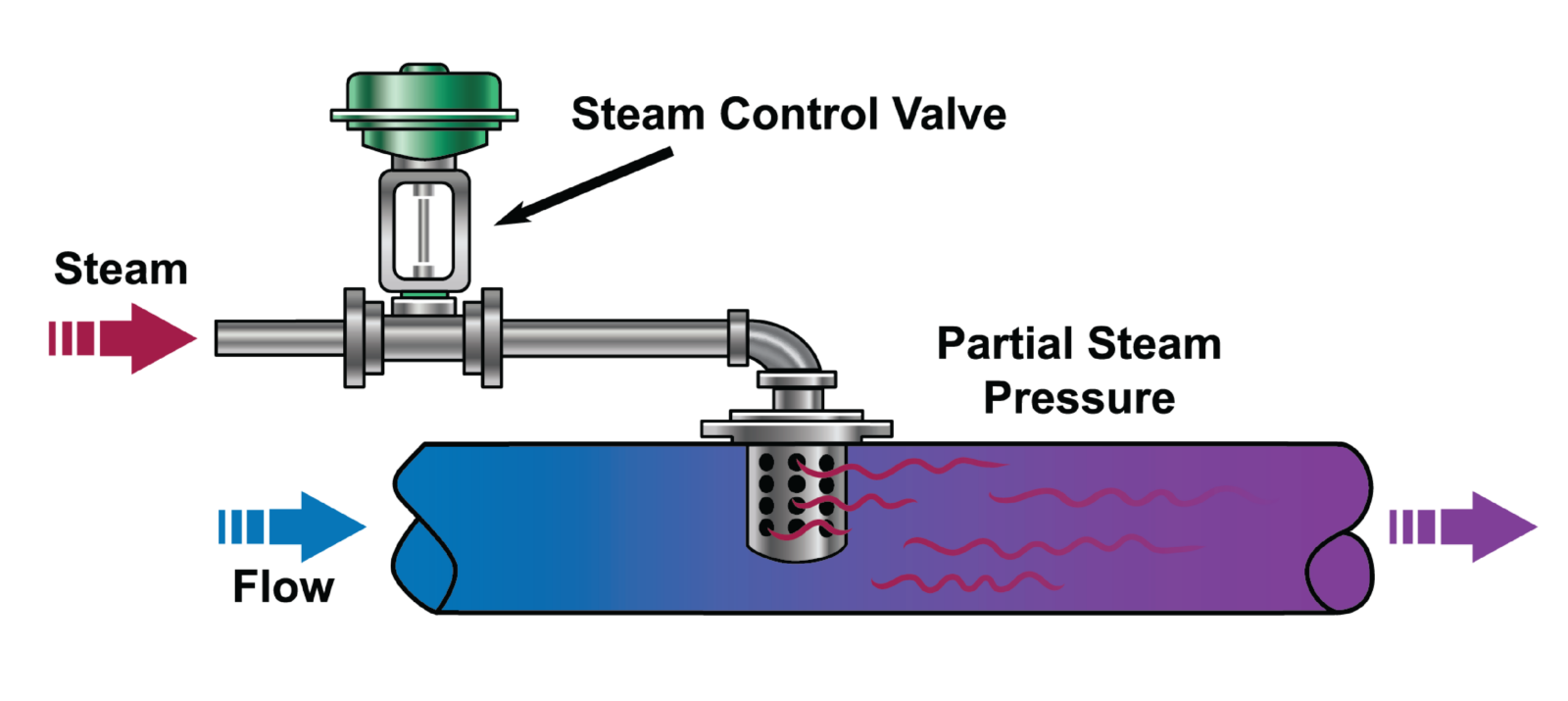

External modulation uses a steam control valve on the supply line to vary the pressure of the steam at the point of injection, varying the pressure changes the steam density and velocity through the nozzle to control the amount of heating. Regulating steam pressure to control heating can result in unstable operation, hammering, and vibration when high or low steam flowrates are required. At low steam flow, i.e., trim heating, the differential between steam pressure and the process can be very small, and a slight fluctuation in either pressure can cause an upset. Alternatively, at high steam flow requirements, i.e., max heating at startup, the orifice or nozzle size will allow more steam than can be condensed, and steam hammer occurs.

DSI controls the injection area rather than steam velocity and density to regulate the amount of heating. An internally modulated heater operates at higher steam velocities compared to external modulation. This higher velocity produces improved, often rapid mixing and nearly instantaneous condensation of the steam into the process fluid.

External modulation

Internal modulation

Get In Touch With Hydro-Thermal

Contact us to learn more or request a quote and we will get back to you shortly.

Direct vs. Indirect Heating

There are two basic types of heat exchangers used to transfer heat between process fluids — direct heat exchange and indirect. Indirect heating is most commonly seen in the form of plate & frame or shell & tube heat exchangers. Any process that does not allow direct mixing of steam and fluid is indirect heating. Heat exchangers transfer heat through a membrane or solid wall. This results in only ~ 83% of the heat energy transferred to the process fluid. In contrast, the remaining energy is discharged in the condensate formed from the steam.

On the other hand, direct heating uses 100% of the steam’s heat energy by adding steam directly to the process fluid.

The benefits of using direct contact heating vs. indirect include:

- Energy savings of 25% or more

- Precise and instantaneous temperature control is possible to within ±1°F

- Reduced footprint for direct steam injection system

- Reduces maintenance via self-cleaning and elimination of a condensate return system

Additional benefits:

- Rapid and uniform heating—important in starches and food product

- Can heat highly viscous fluid

- Handles fluids that are difficult to heat—avoids “bake-on”; abrasive slurries

- Eliminates plugging and fouling of the heat transfer surface

- Rapid response time

Understanding Heating Systems: Direct Steam Injection & Heat Exchangers

Various methods efficiently transfer thermal energy in industrial heating. Heat exchangers, for example, use a surface to transfer heat between two fluids without direct contact. However, direct steam injection (DSI) is a powerful alternative in several forms, each with varying complexity and temperature control.

A heat exchanger is a device that transfers heat from one fluid (liquid or gas) to another without the two fluids mixing. It typically consists of metal plates, tubes, or coils that separate the fluids while allowing efficient heat transfer. Heat exchangers are commonly used in industrial processes, power plants, and food processing.

Drawbacks of a Heat Exchanger are:

- Slower Heating: Relies on indirect heat transfer, making it less responsive

- Fouling & Scaling: Minerals, debris, and biological buildup reduce efficiency and require frequent maintenance

- Larger Footprint: Bulkier and requires more space for installation

- Lower Energy Efficiency: Some heat energy is lost in transfer, reducing efficiency

- Higher Maintenance Costs: Regular cleaning and repairs increase operational expenses

- Limited Temperature Control: Lags in response compared to direct heating methods

The externally modulating sparger tube (MST) heater consists of a spring controlled, variable-injection sparger tube inside a cast process flow body. In response to a temperature sensor, the external flow control valve modulates the steam to a spring-loaded piston. MST heaters work reasonably well on clear liquids and some low solids solutions. Still, they are subject to severe clogging and steam hammer if frequent maintenance is not performed. In typical water heating applications, these devices typically require monthly tear down and acid bath cleaning. Since the steam flow is dependent upon a spring-loaded valve, accurate temperature control is difficult once the spring begins to wear.

Additionally, if low (trim heating) or high steam flow is required, the spring mechanism can have difficulty with accurate or stable control. Spring failure is a common issue with this type of heater. Additional drawbacks of sparge tubes are:

- Requires external steam control valve

- Very high maintenance

- Prone to scaling and fouling

- Steam hammer common

- Limited temperature control due to external control

- Internal spring prone to wear and breakage

Steam Sparging is the oldest, most straightforward and least complicated technique for mixing steam with liquid or slurry to affect heating. It is injecting steam directly into a fluid-filled tank. Though considered inexpensive and straightforward, sparging is very inefficient, and the operation invariably results in:

- Poor heat injection economics due to steam energy escaping from vessels without condensing

- High maintenance costs for tanks, sensors, and piping are the norm if the equipment operates outside the design parameters

- Equipment failure (both vessel and sparger pipes) due to the vibration associated with steam hammer when not operated within their narrow design envelope

- Usually less than satisfactory on/off process control, a sparger is the least controllable direct steam injection heating method

- Non-uniform heating

Mixing Ts combine separate streams of steam and cold water to produce heated water. Because accurate temperature control is difficult to maintain with this method, Mixing Ts are not the best choice for process fluids. When used for water, Mixing Ts are prone to scaling, fouling, and excessive hammer. Their operation often requires steam and water pressure to be very close to each other for balanced mixing. When either steam or water pressure fluctuates slightly, the higher-pressure line can overcome the other and backfill the piping. This can result in live steam discharging the system. The drawback of Mixing Ts are:

- Very high maintenance

- Prone to scaling and fouling

- Steam hammer is common

- Potentially very dangerous due to live steam being close to human contact

- Limited temperature control